IMPORTANT INFORMATION

This step by step guide covers the basics of a power flush. For advice on specific problems or situations refer to the POWER FLUSHING SUPPORT section of our web site, or call Kamco on 01727 875020. 1 WHAT'S IN THE BOX

- 1. CLEARFLOW PUMP

- 2. FLOW AND RETURN HOSE (2x 5m)

- 3. DUMP HOSE (8m)

- 4. WATER INLET HOSE (8m)

- 5. OVERFLOW HOSE (3m)

- 6. CIRCULATOR PUMP ADAPTER HOSES

- 7. KAMCO CHEMICAL STARTER PACK Also included: BSP Adapters (10 pack)

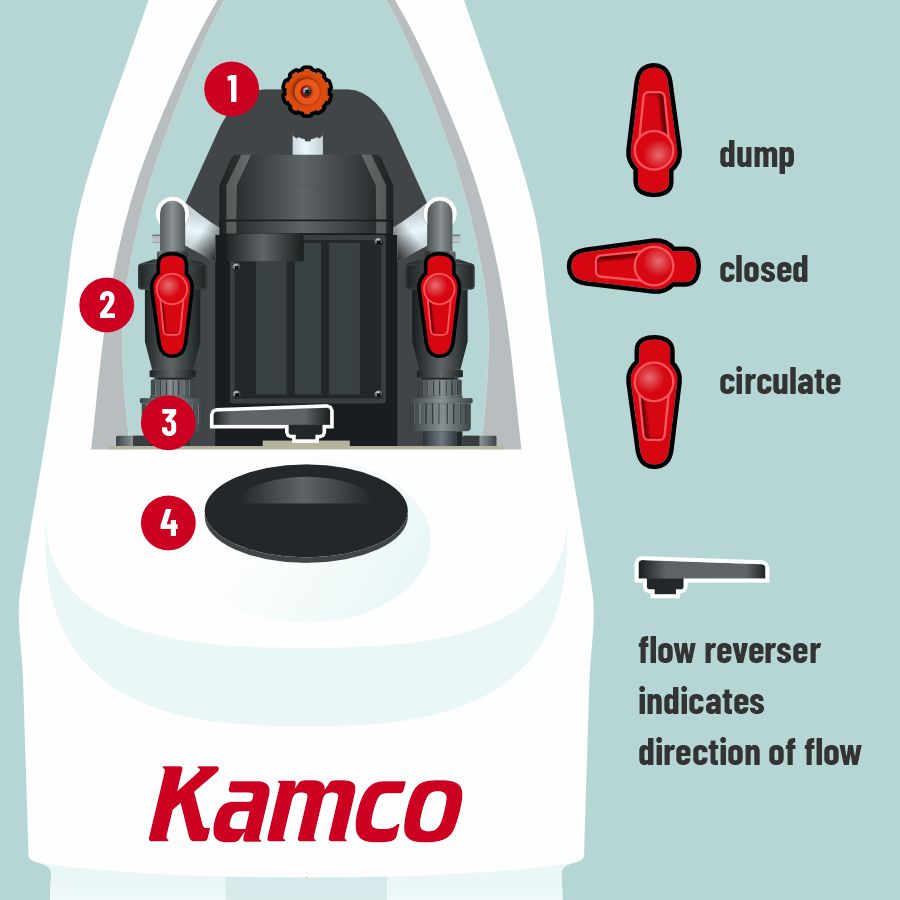

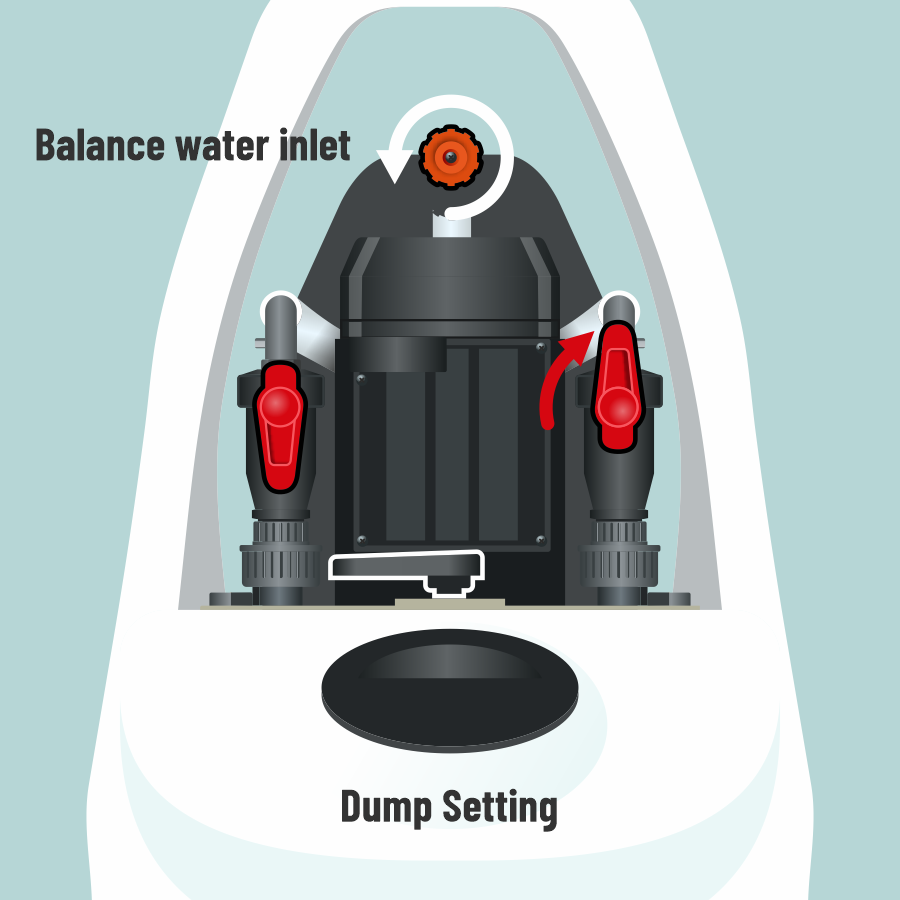

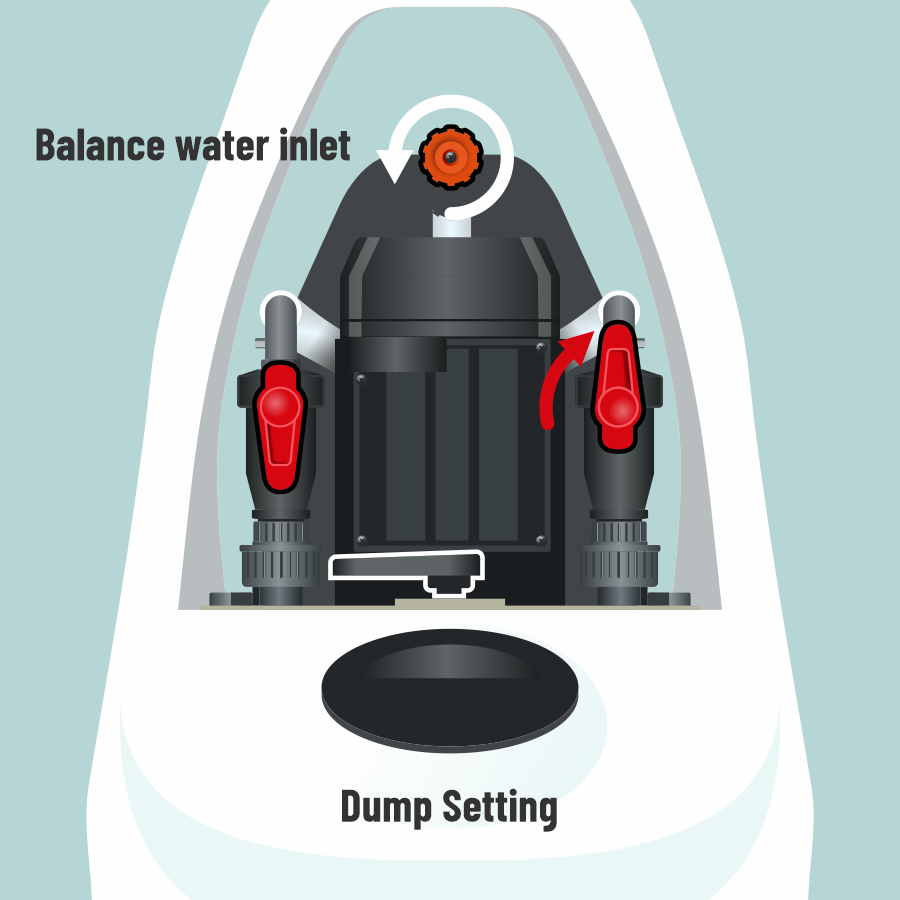

2 VALVES AND FLOW REVERSER

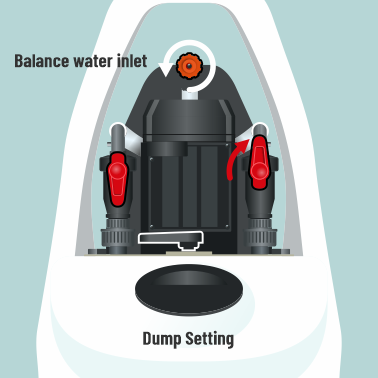

- 1. WATER INLET VALVE

(location may vary) - 2. ISOLATION VALVES (2x)

- 3. FLOW REVERSER LEVER

- 4. HOLDING TANK ACCESS CAP

3 LOCATING THE CLEARFLOW PUMP

- Locate close to supply of mains water

- Locate close to foul water waste drain

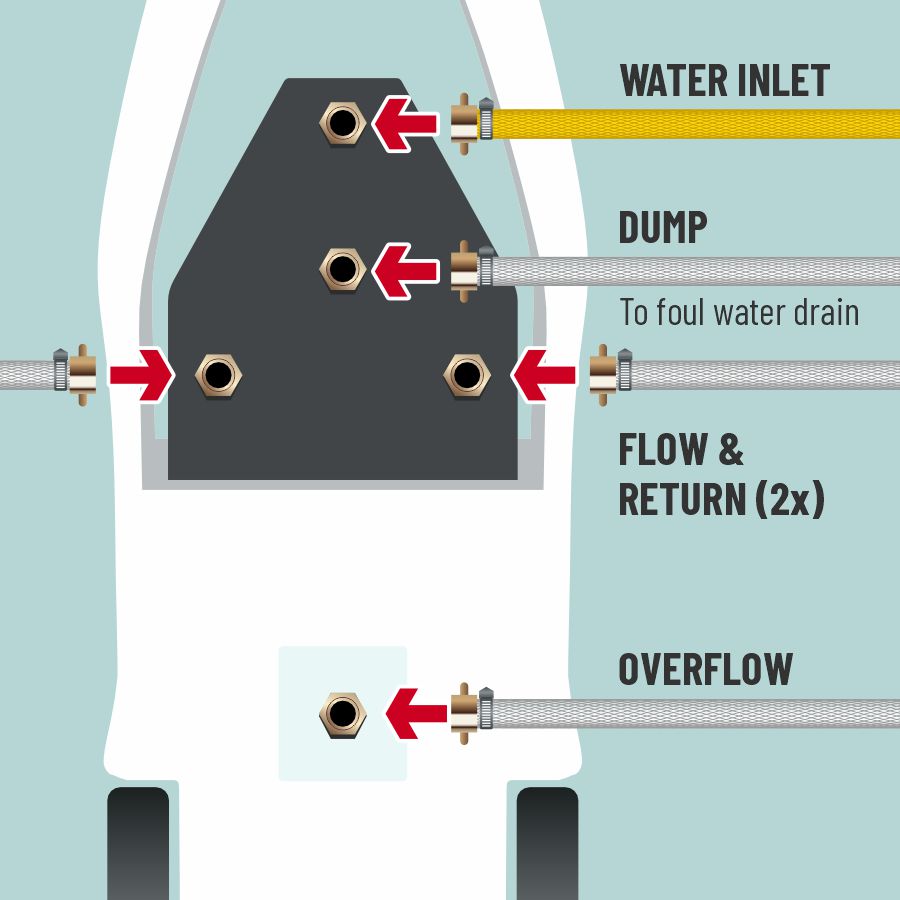

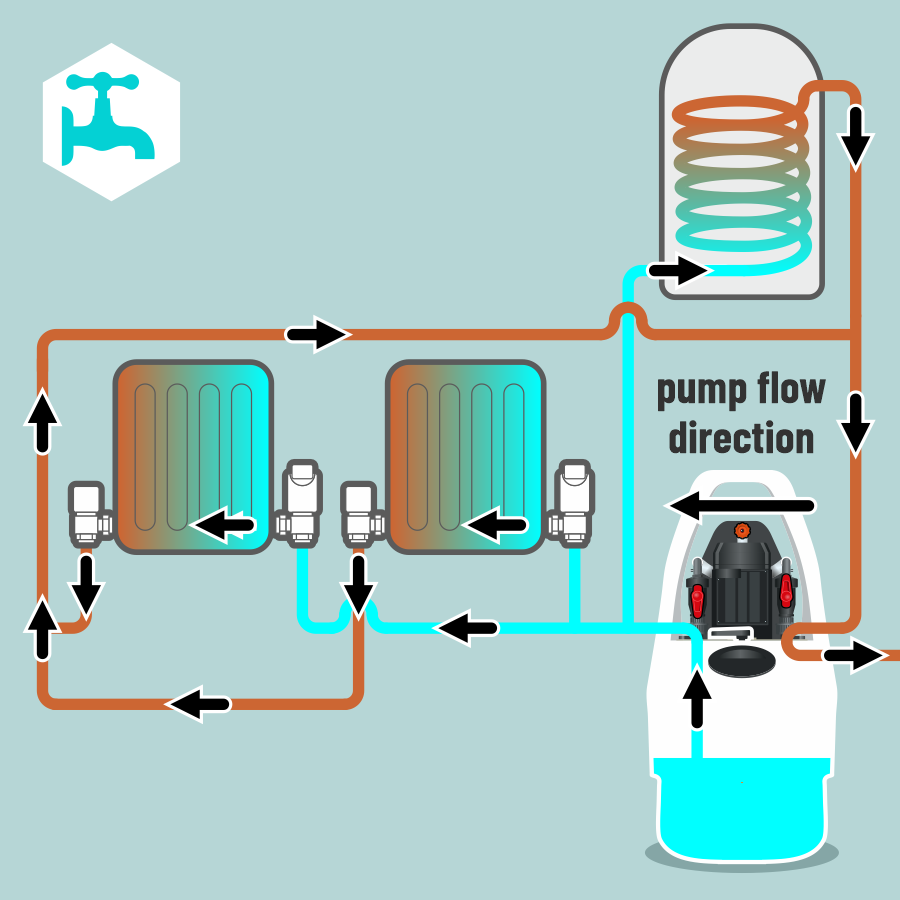

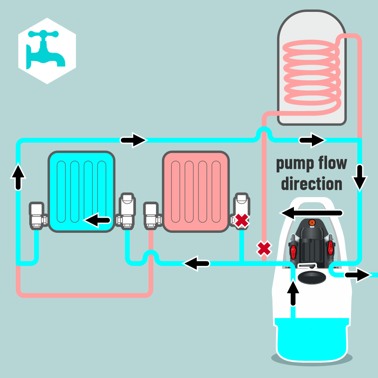

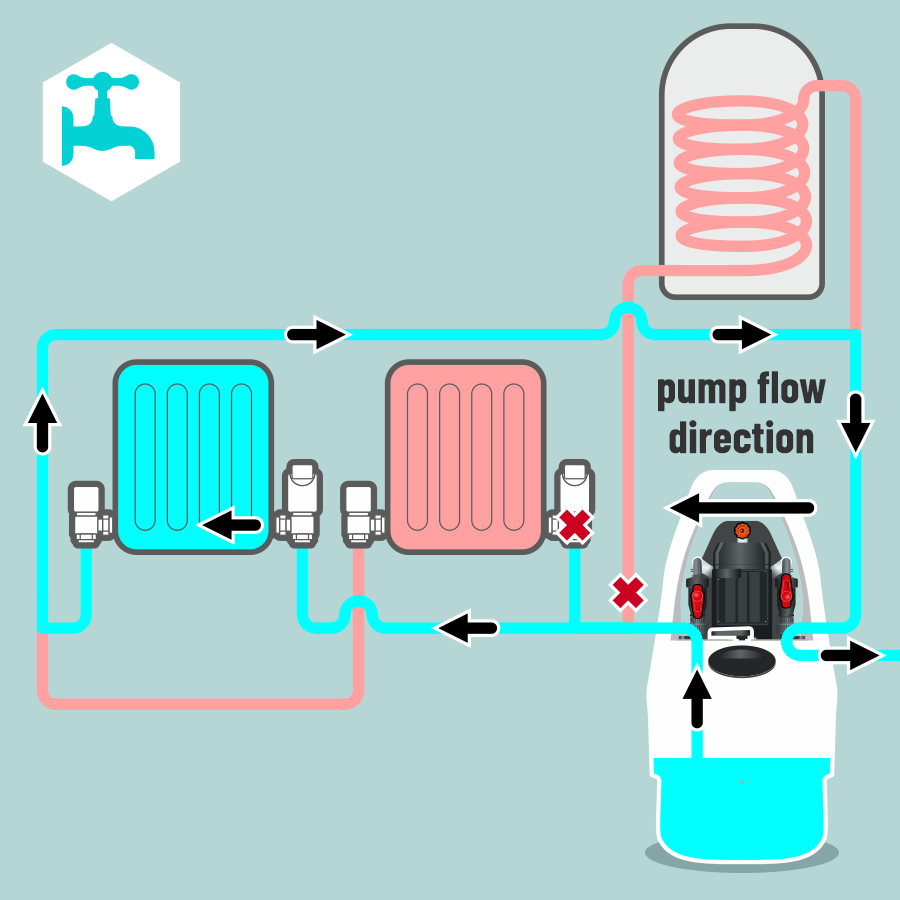

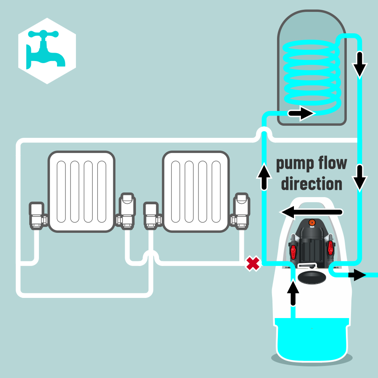

4 CONNECTING HOSES TO PUMP

- Connect hoses firmly by hand

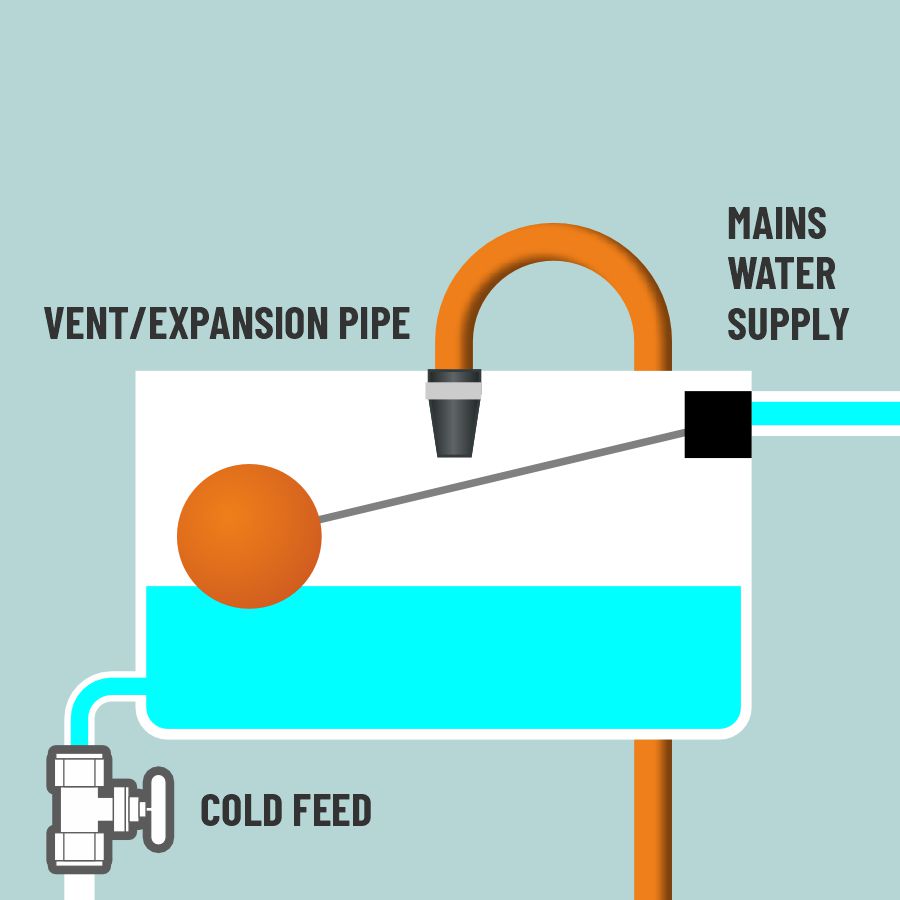

5 SEAL OFF VENTED SYSTEMS

- Isolate mains water supply

- Isolate cold feed

- Fit temporary cap to expansion/vent pipe

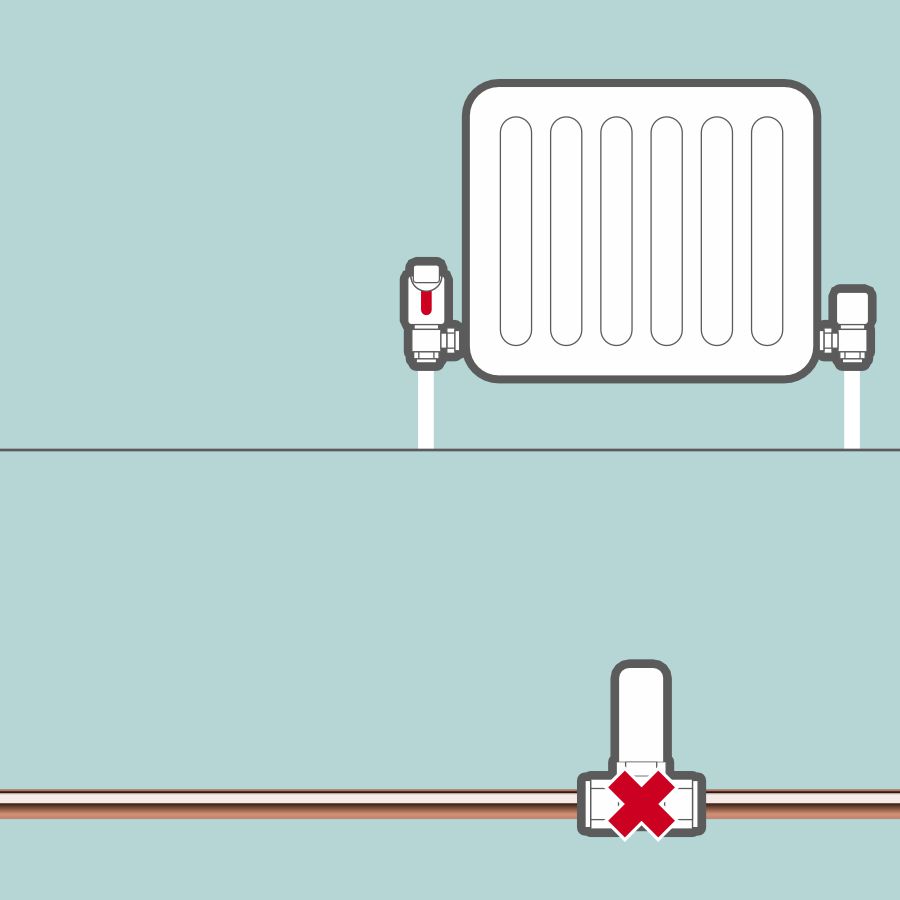

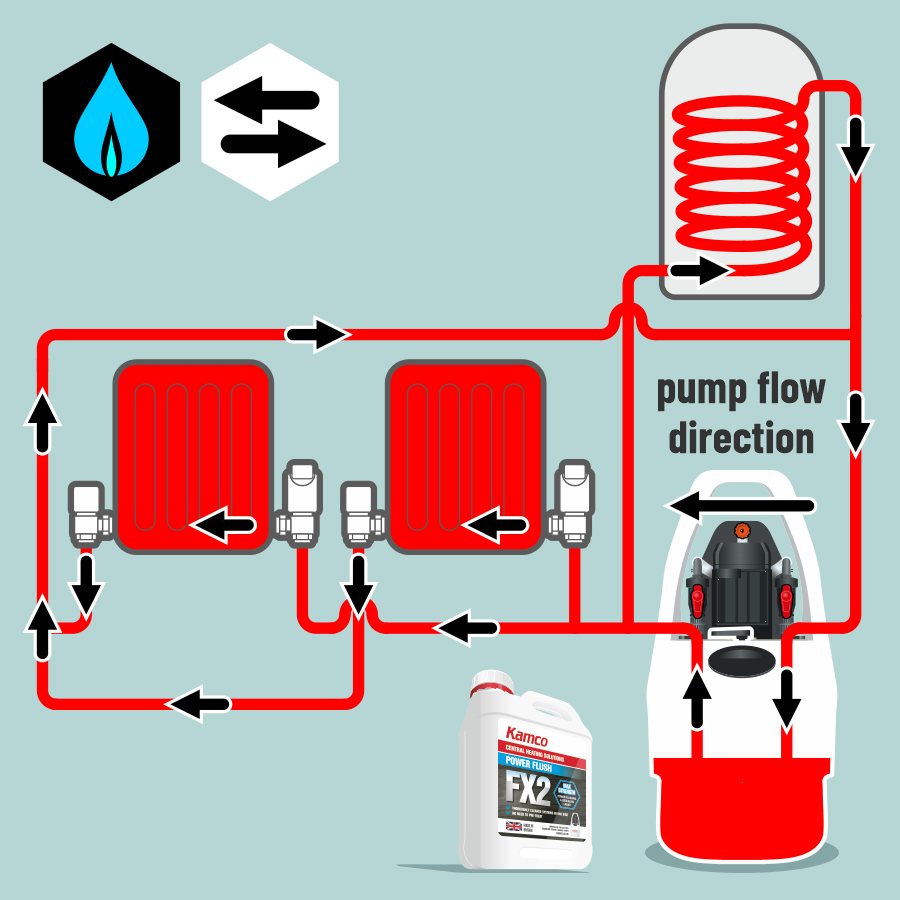

6 ADJUST THERMOSTATIC VALVES

- Set thermostatic radiator valves to maximum

- Remove thermostatic valve heads

- Close by-pass

- Close auto by-pass (if present )

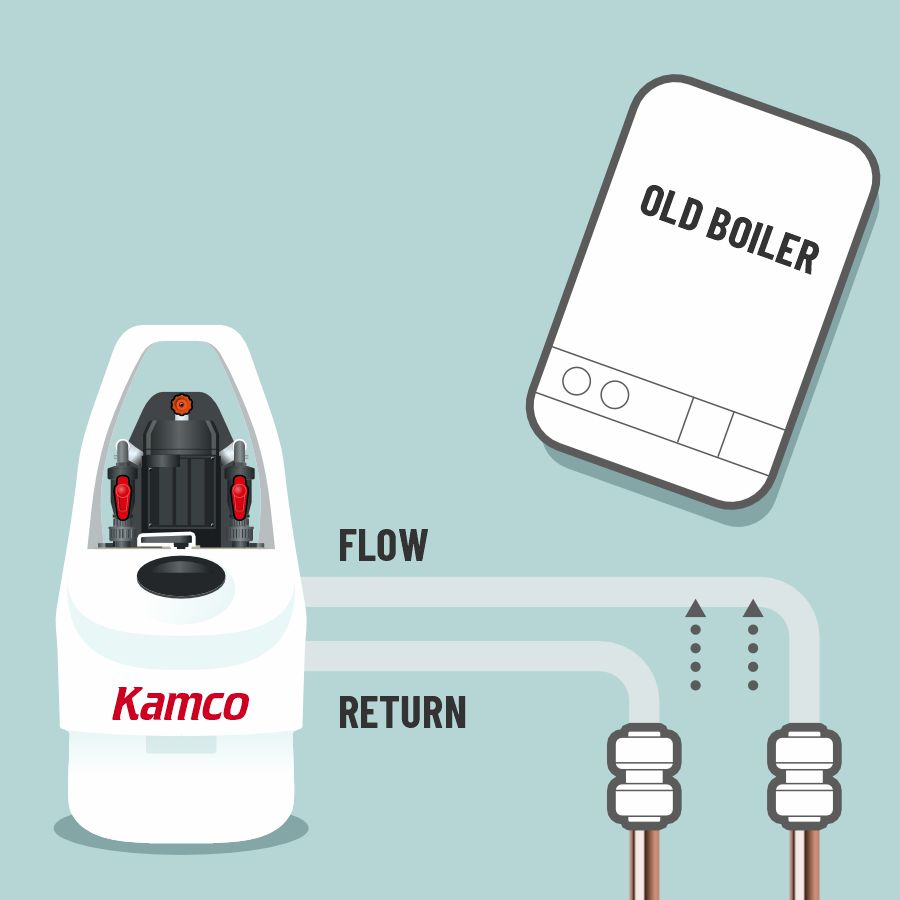

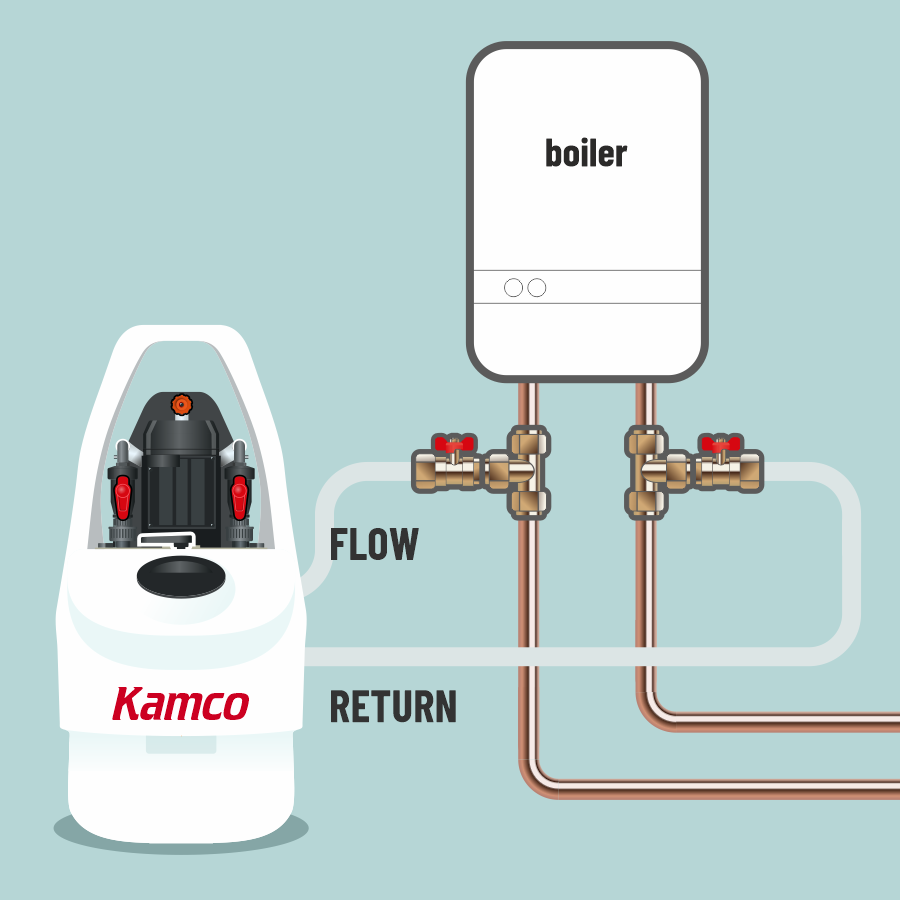

7 METHODS FOR CONNECTION

- Connect across flow and return pipes

after boiler has been removed

REPLACING THE BOILER

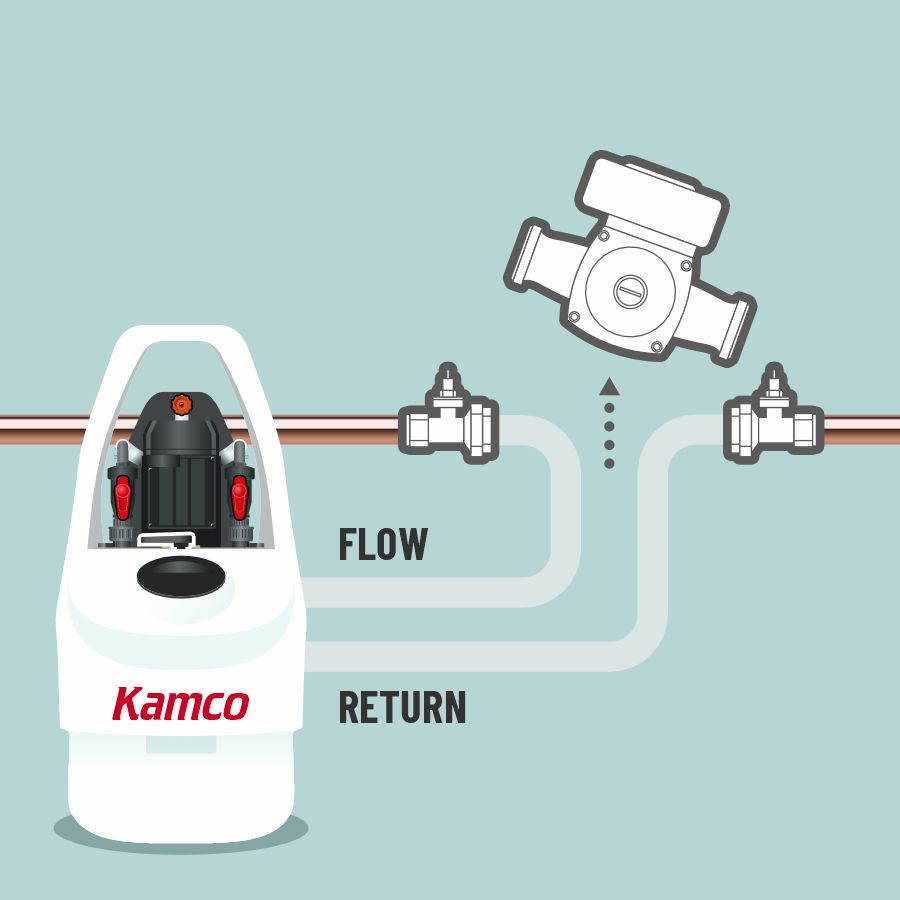

8 METHODS FOR CONNECTION

- Connect to circulator pump connections using adapter hoses supplied

REMOVE CIRCULATOR PUMP

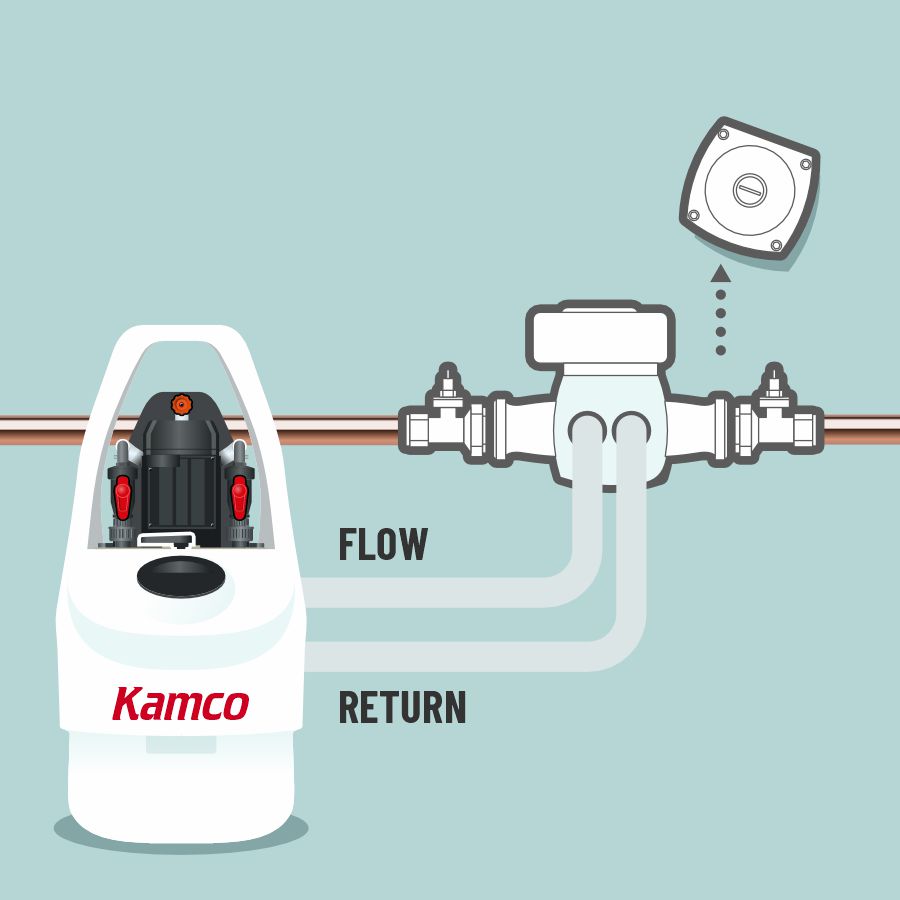

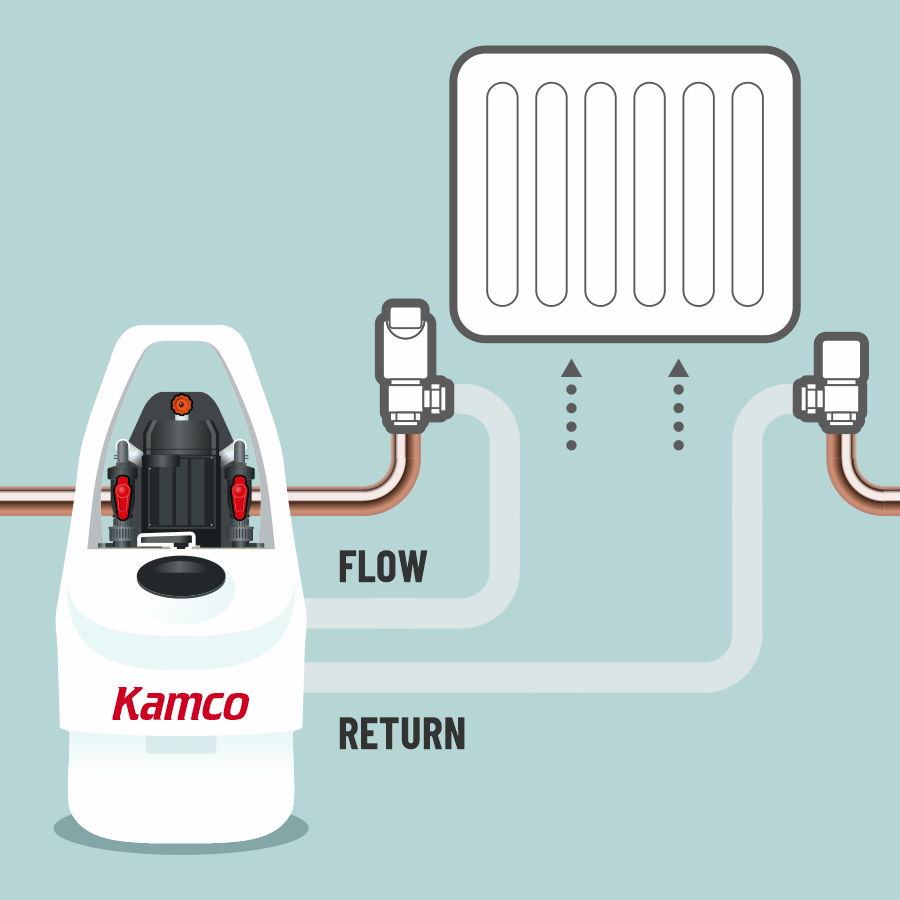

9 METHODS FOR CONNECTION

- Remove circulator pump head only

- Connect CP2 or circulator pump body

- Connect Clearflow Pump with hoses

supplied with CP2

CP2 CIRCULATOR PUMP ADAPTER

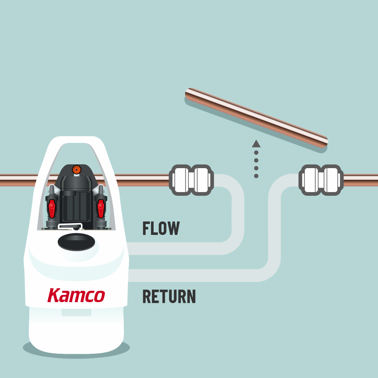

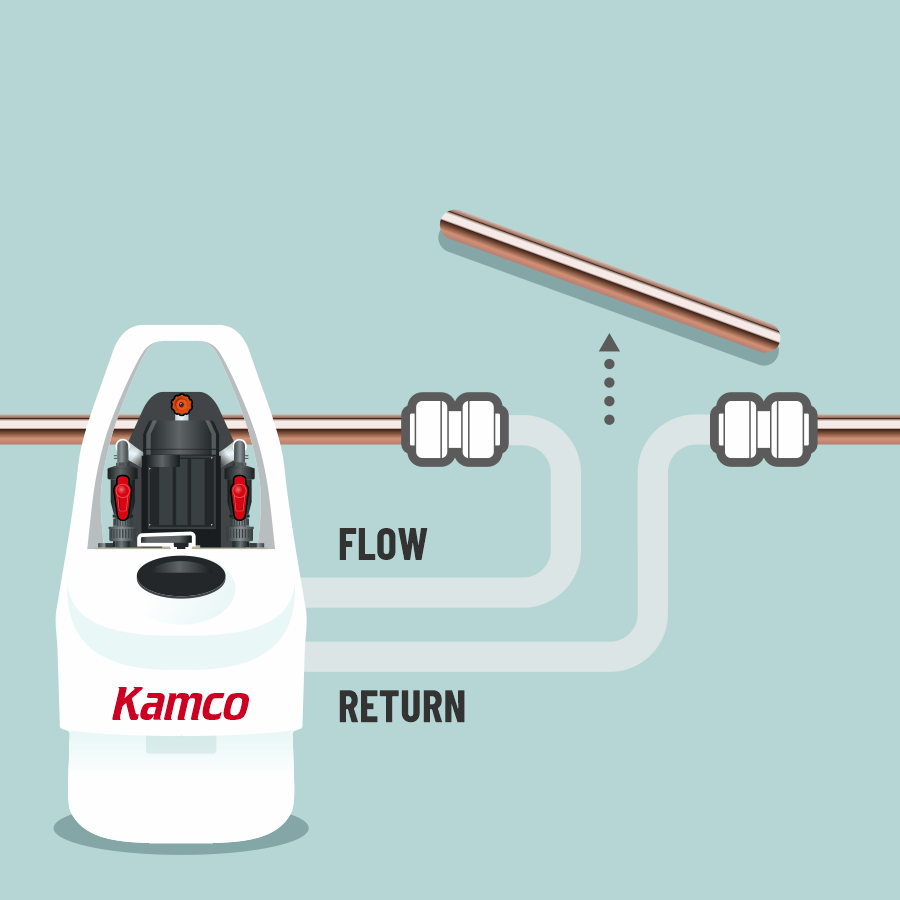

10 METHODS FOR CONNECTION

- Remove a section of copper pipe

- Connect with push fit connectors

BREAK INTO COPPER PIPE

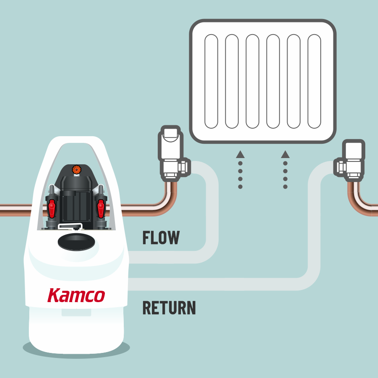

11 METHODS FOR CONNECTION

- Connect Clearflow to radiator valve bodies

(not suitable for microbore systems)

REMOVE A RADIATOR

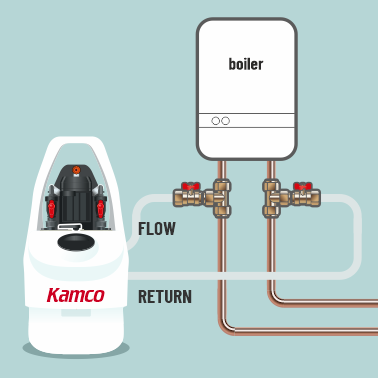

12 METHODS FOR CONNECTION

- Tees and valves may be fitted to boiler tails for convenient connection in the future

CONNECT TO BOILER TAILS

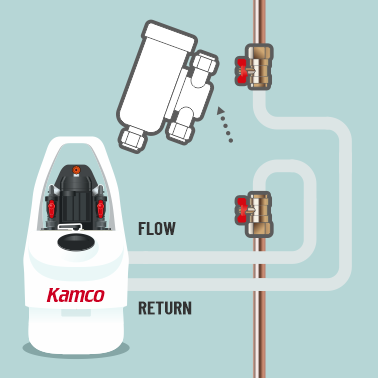

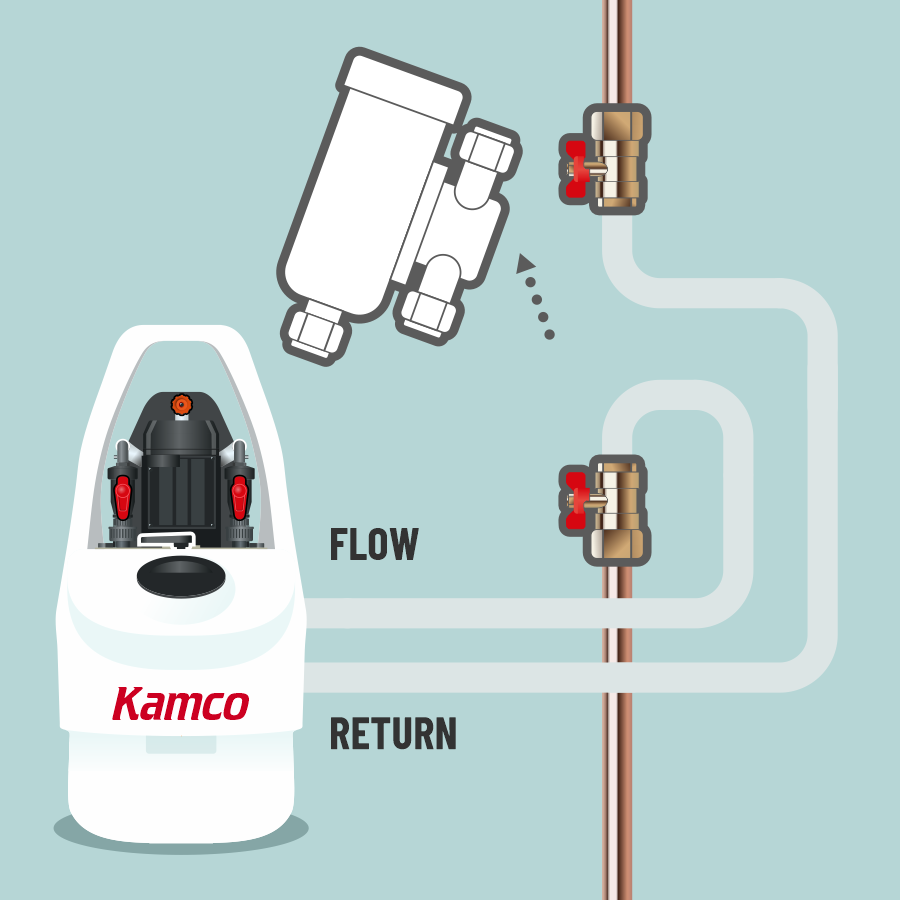

13 METHODS FOR CONNECTION

- Connect to pipework/isolation valves after removal of filter

REMOVE MAGNETIC FILTER

14 FASTER POWER FLUSHING

- Quickly captures magnetic debris

- Speeds up flushing process

- Reduces water usage

- Customers can see what WAS in their system

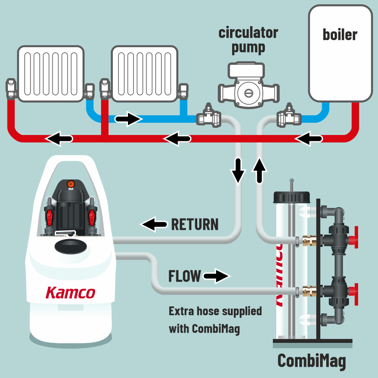

Kamco CombiMAG

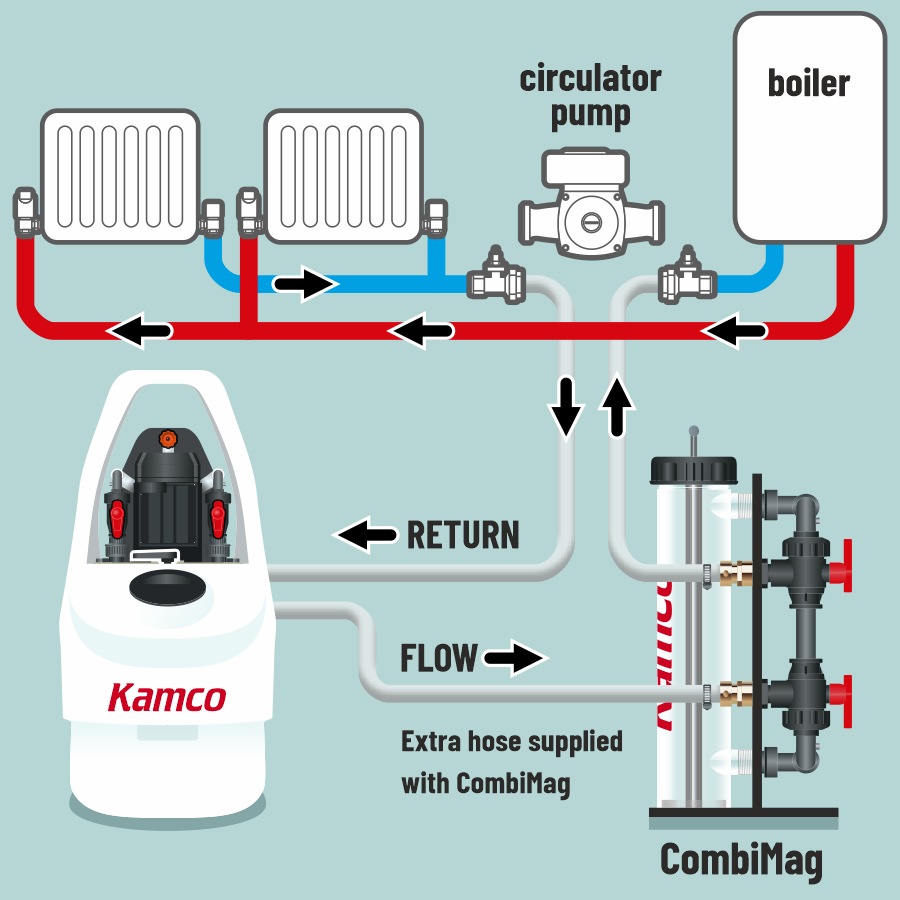

15 CONNECTING CombiMAG

- Connect CombiMAG to system using

hoses and adapters supplied

with CombiMAG - CombiMAG may be connected along side Clearflow in a variety of locations

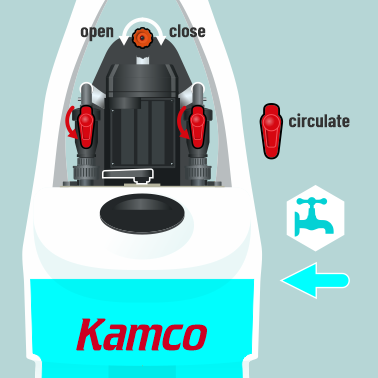

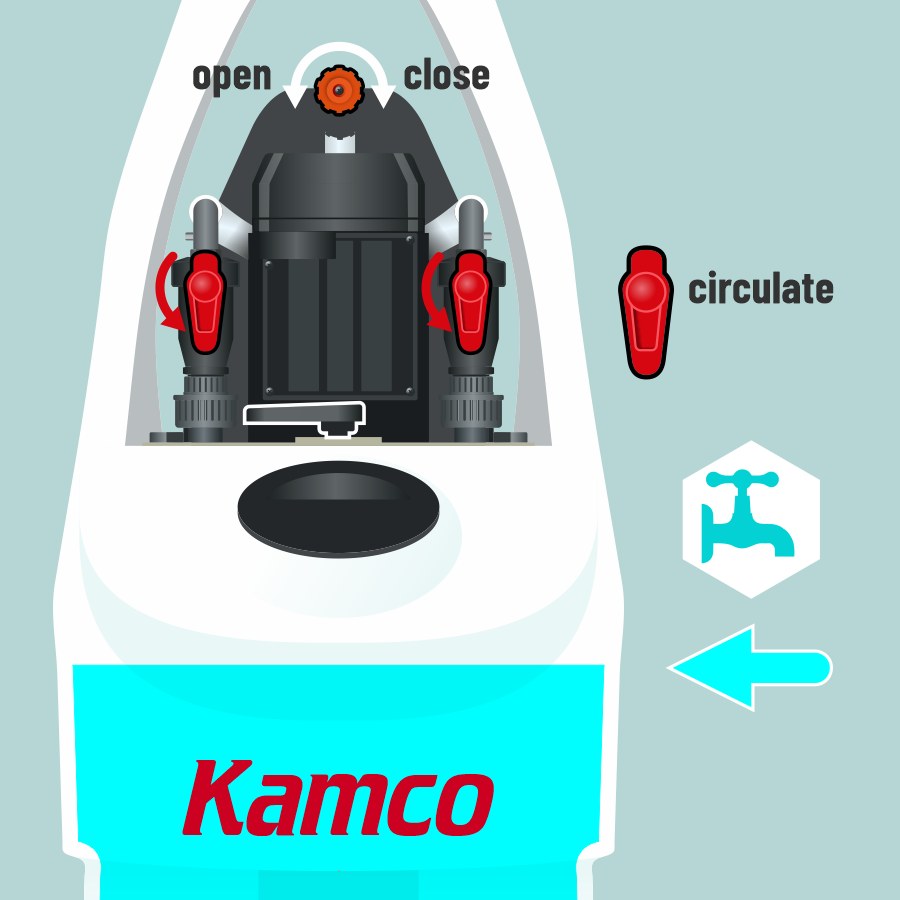

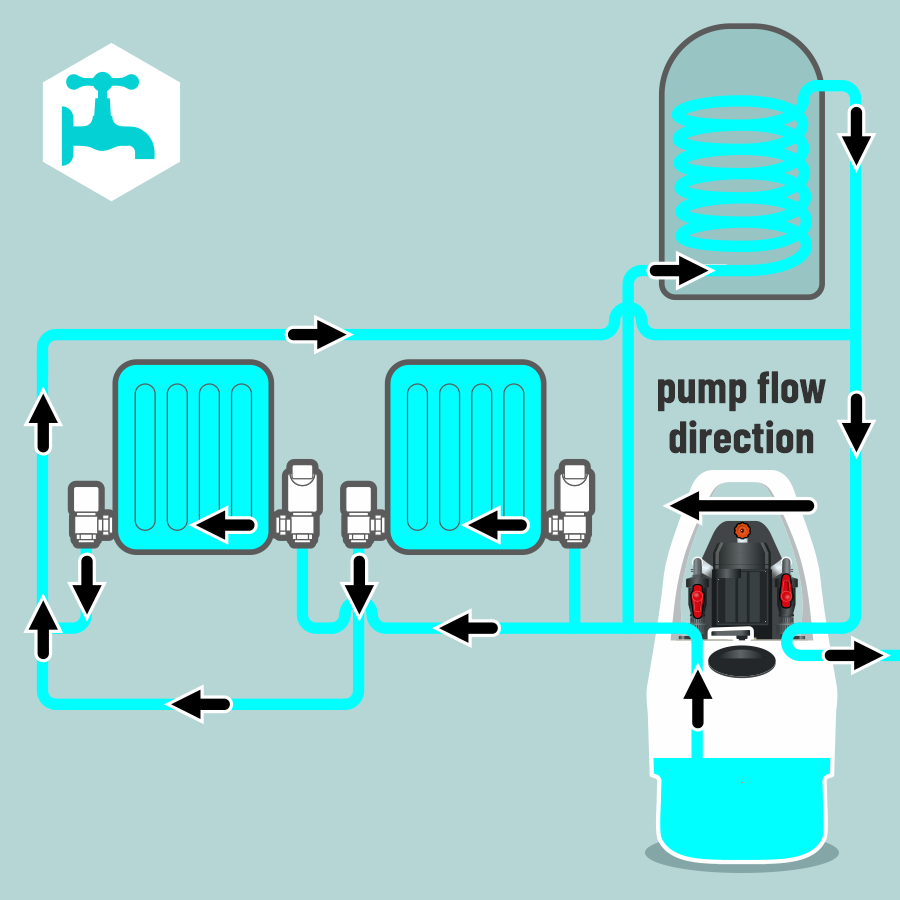

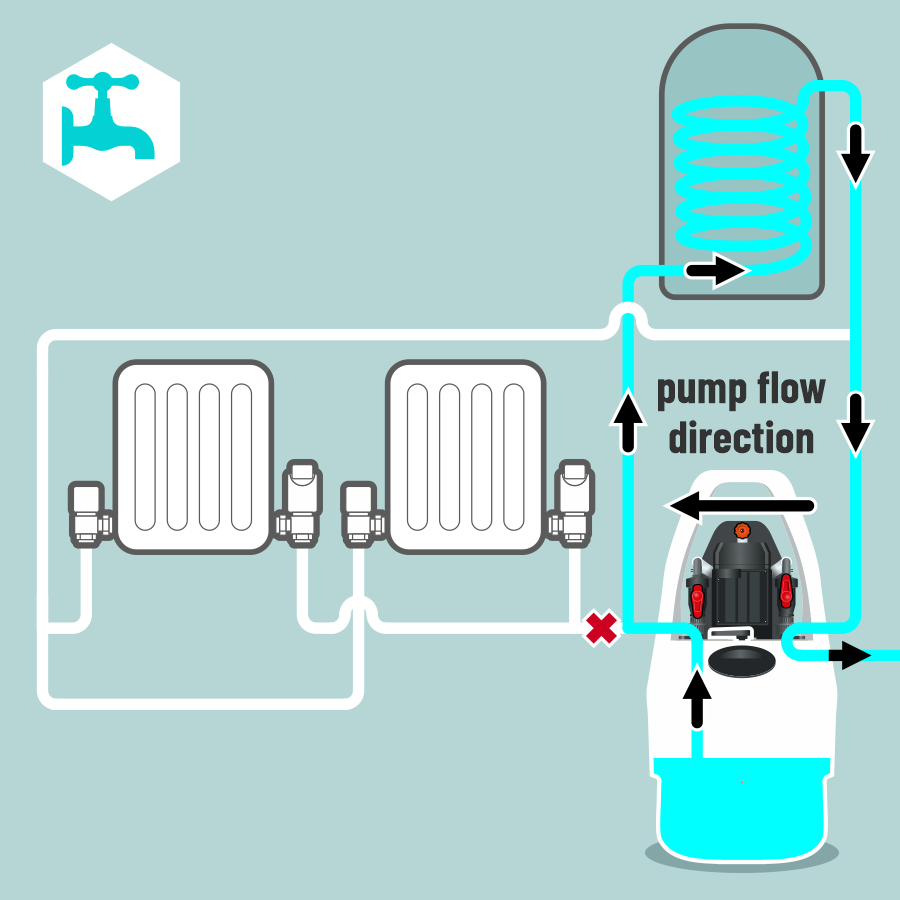

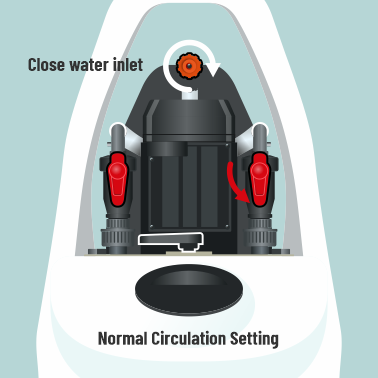

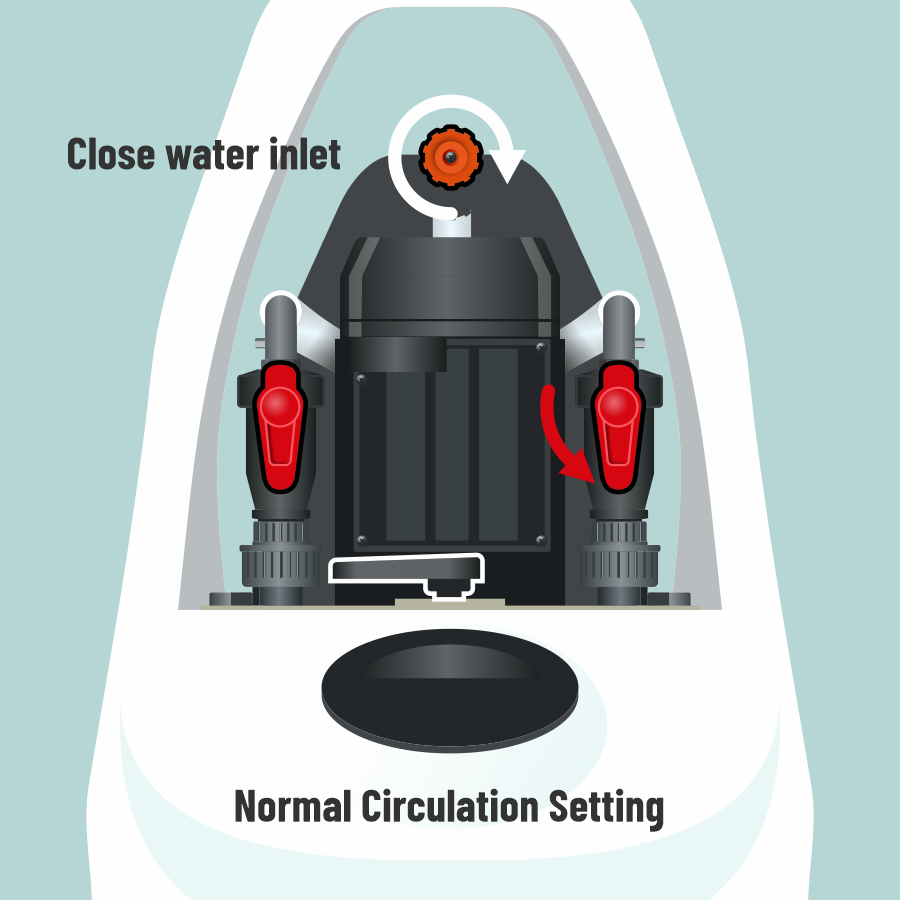

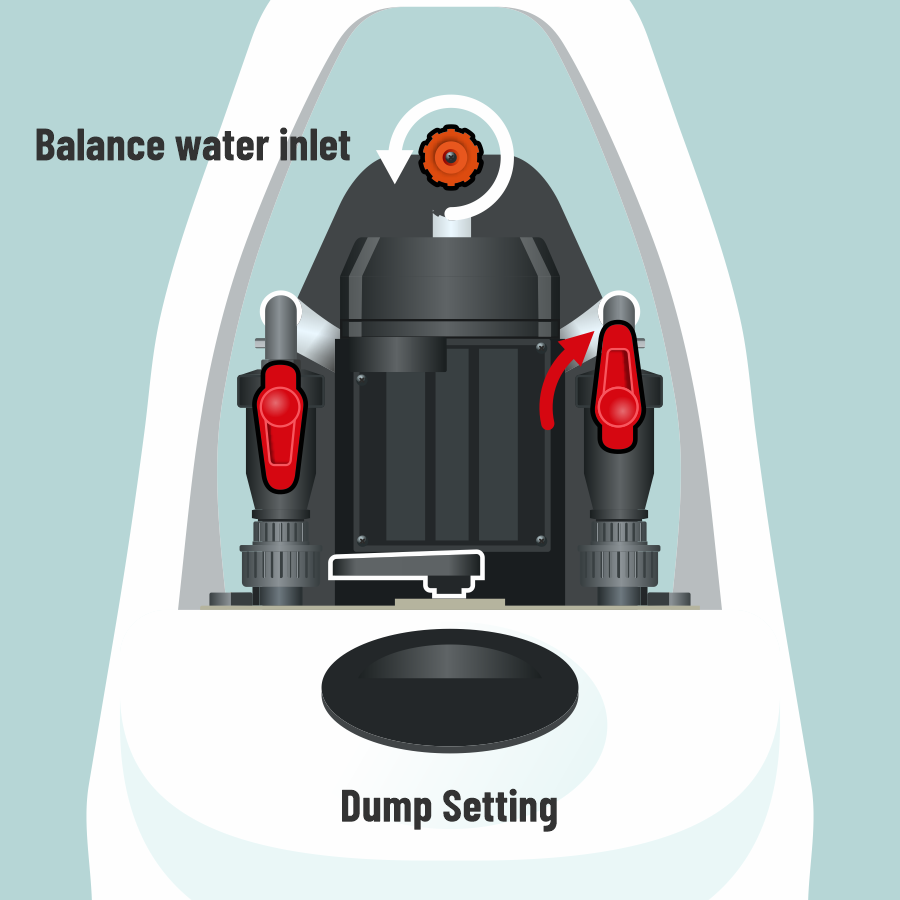

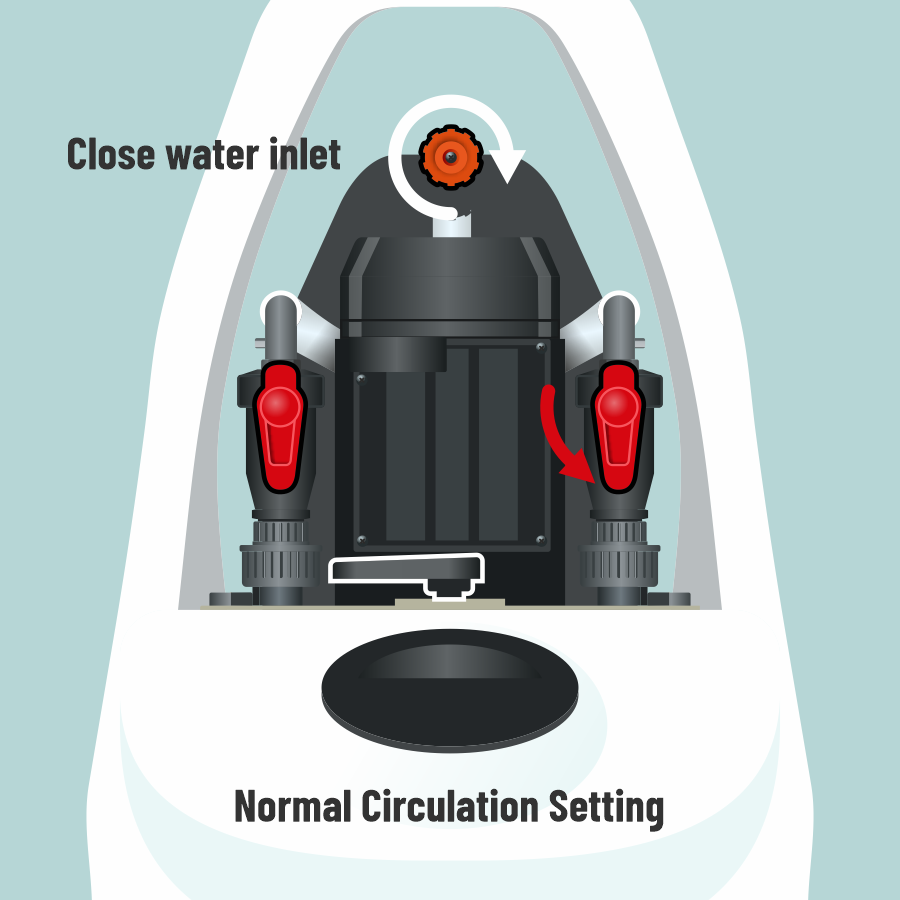

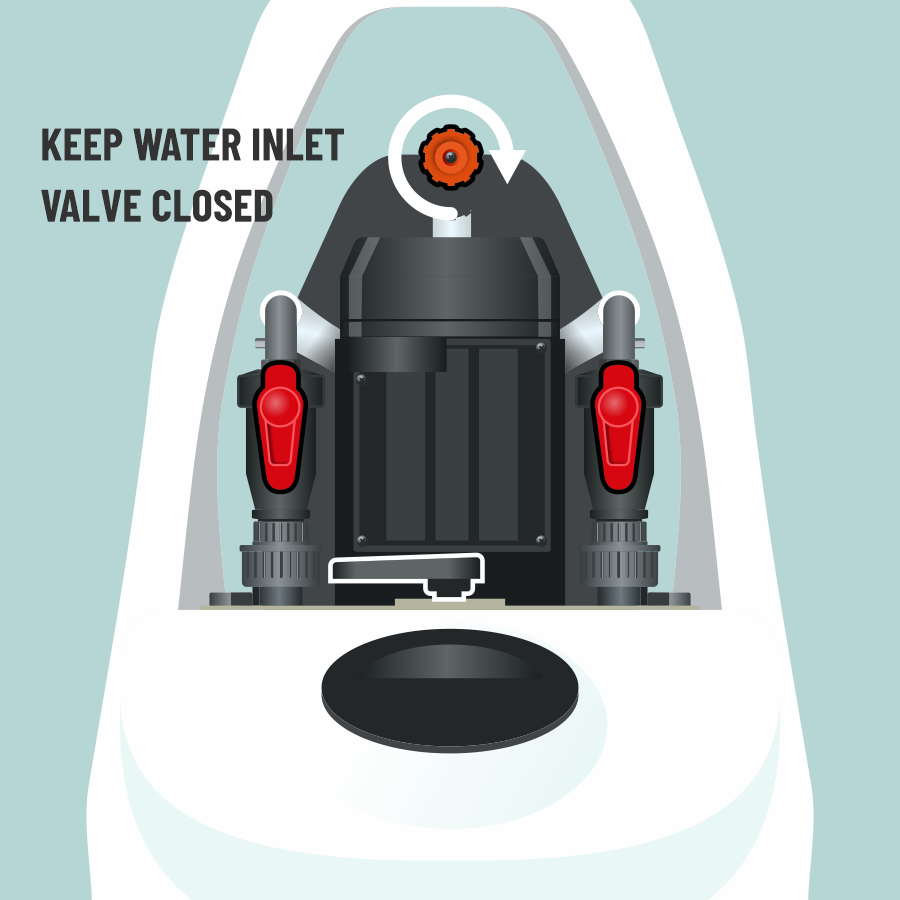

16 PREPARE CLEARFLOW PUMP

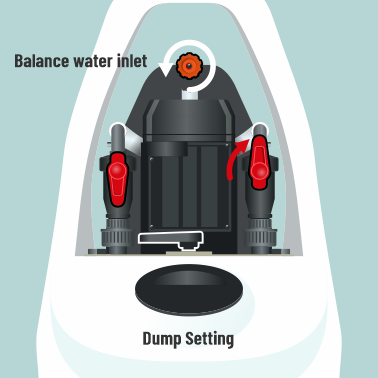

- Open water inlet valve

- Allow holding tank to fill to half way

- Close water inlet valve

- Set both isolation valves to downward "circulate" position

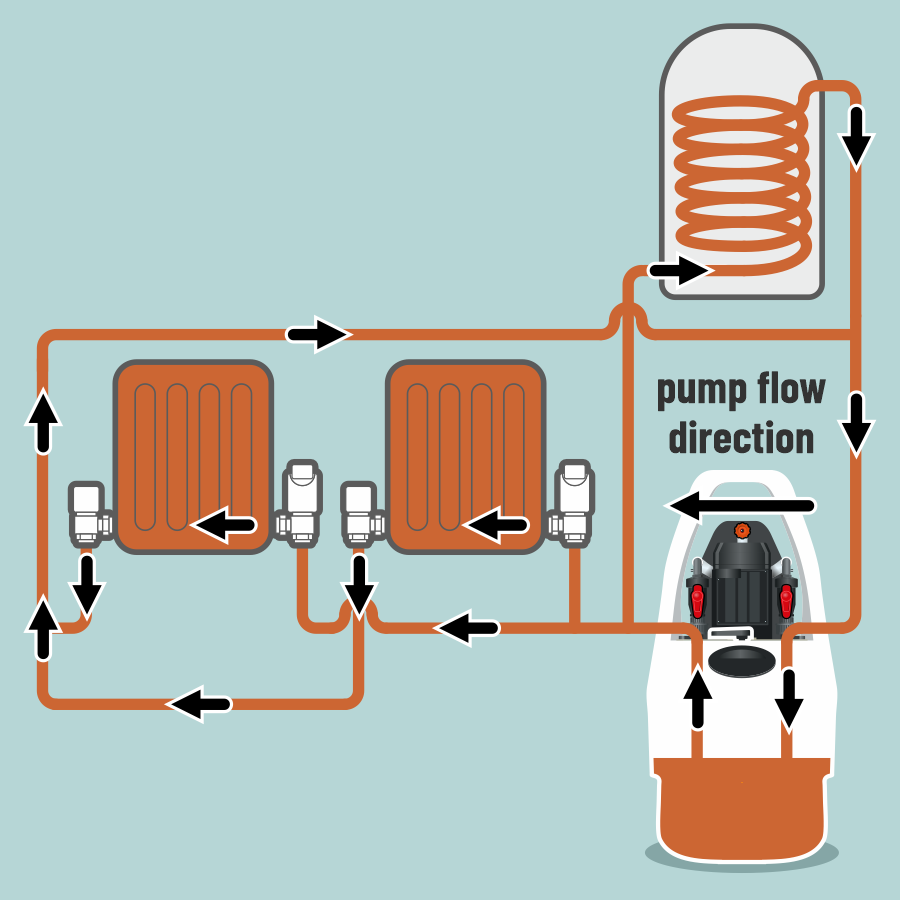

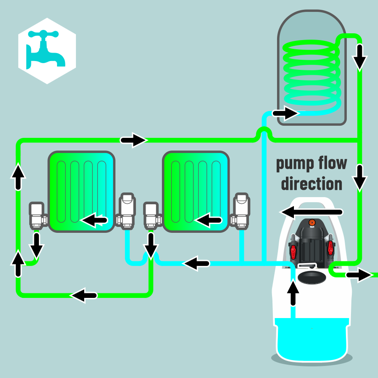

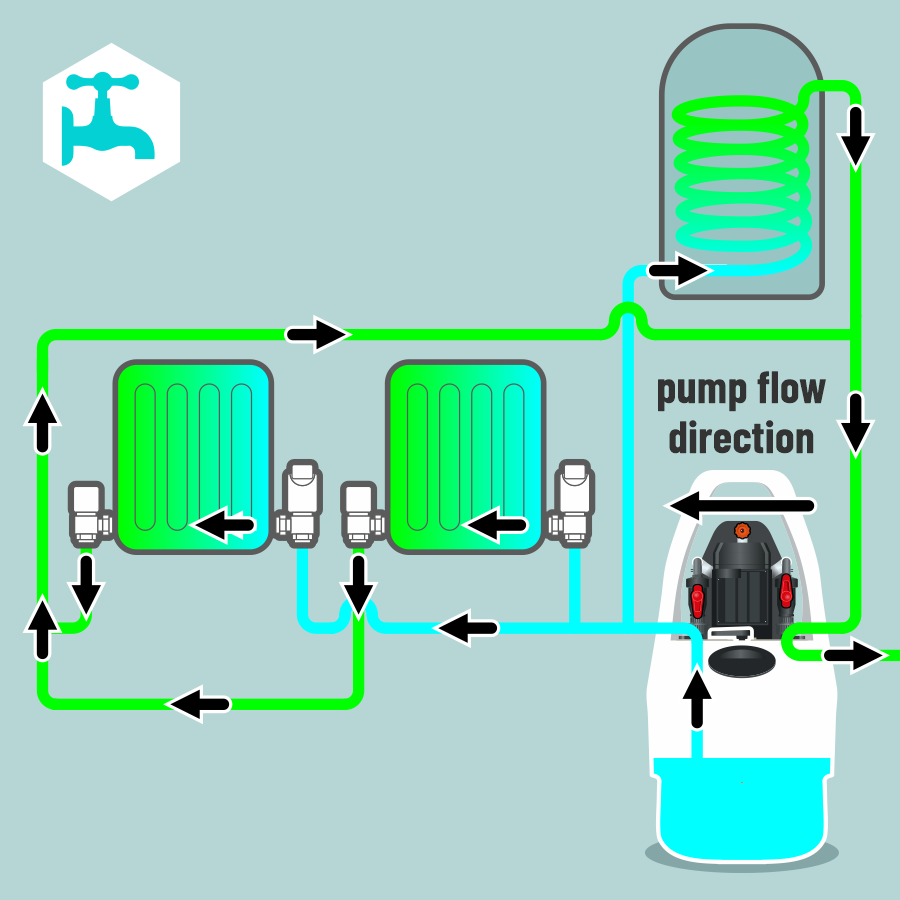

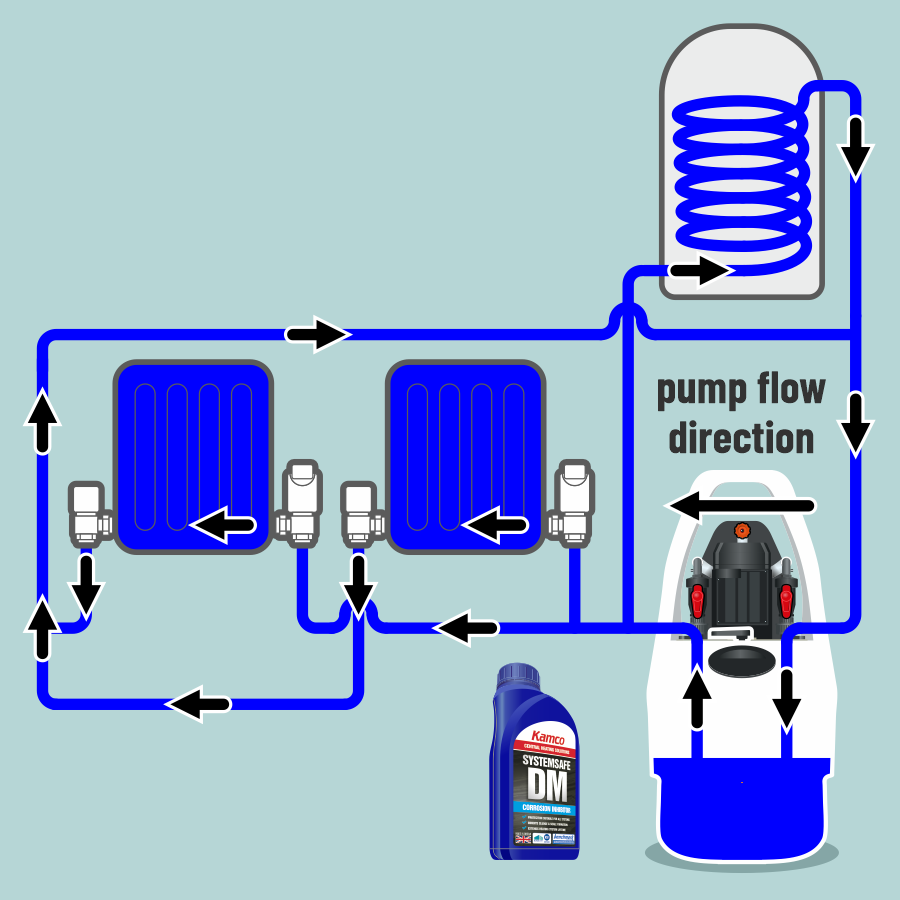

17 POWER FLUSHING BEGINS

- System is wide open

- Activate main power switch on top of the motor housing

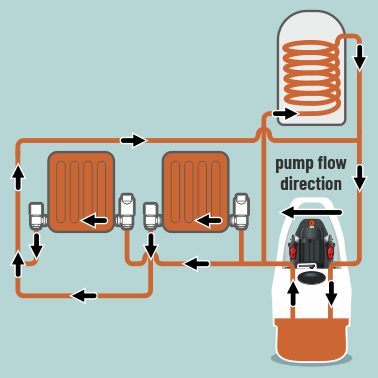

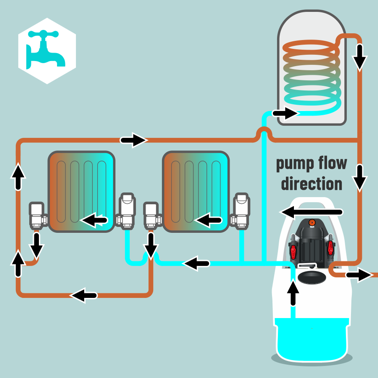

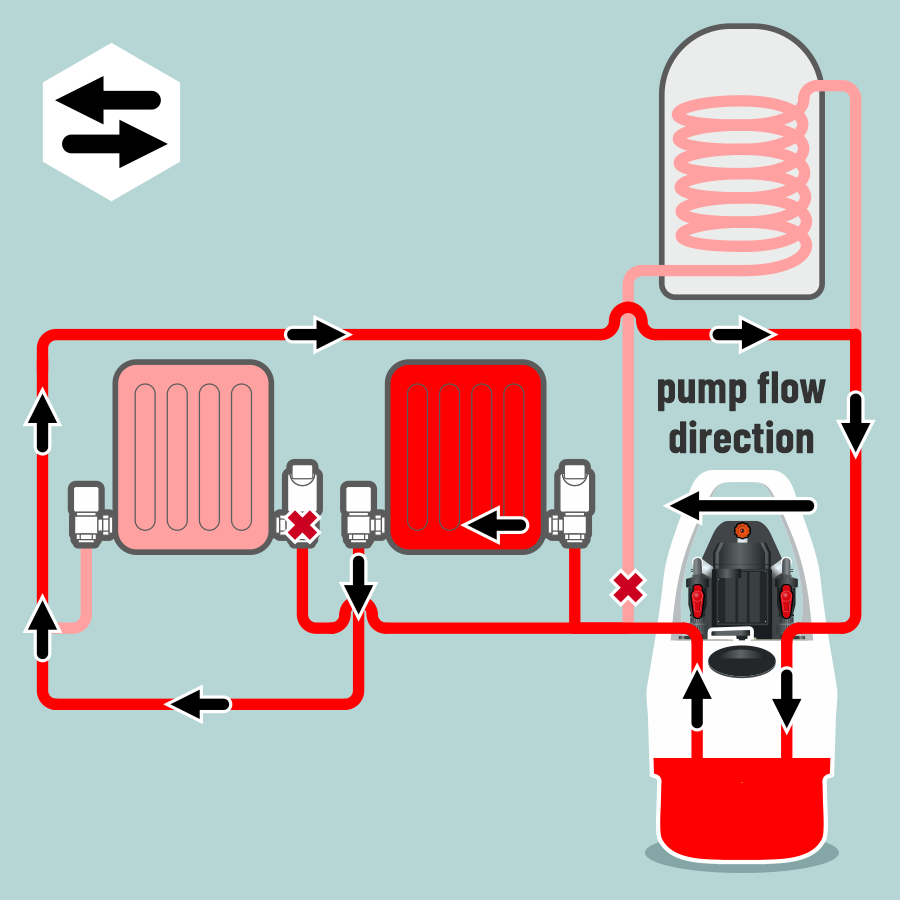

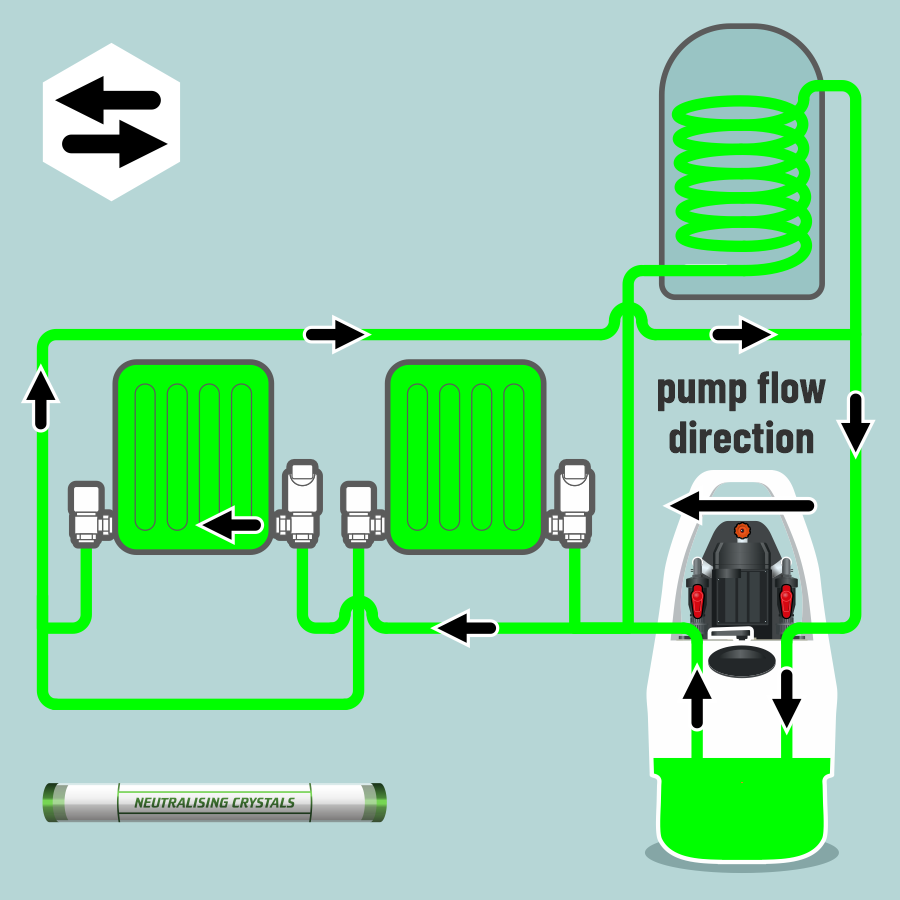

18 REVERSE DIRECTION OF FLOW

- Rotate flow reversal lever through 90°

from left to right - System is wide open.

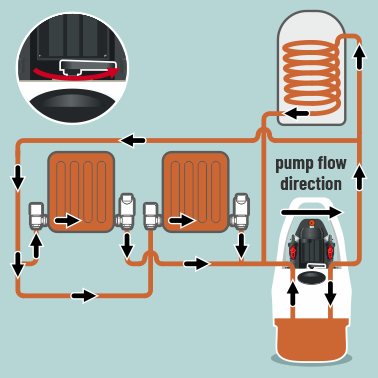

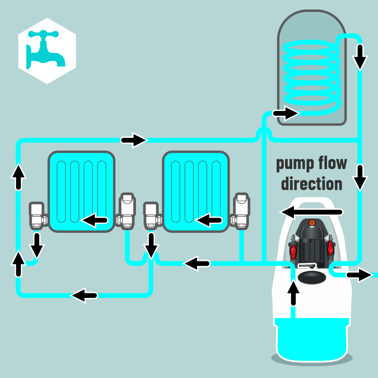

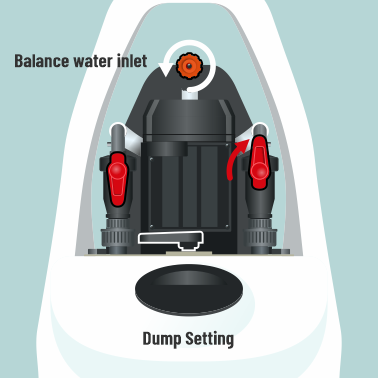

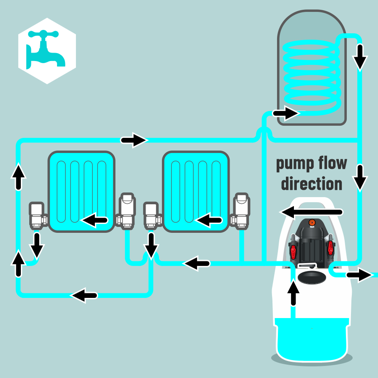

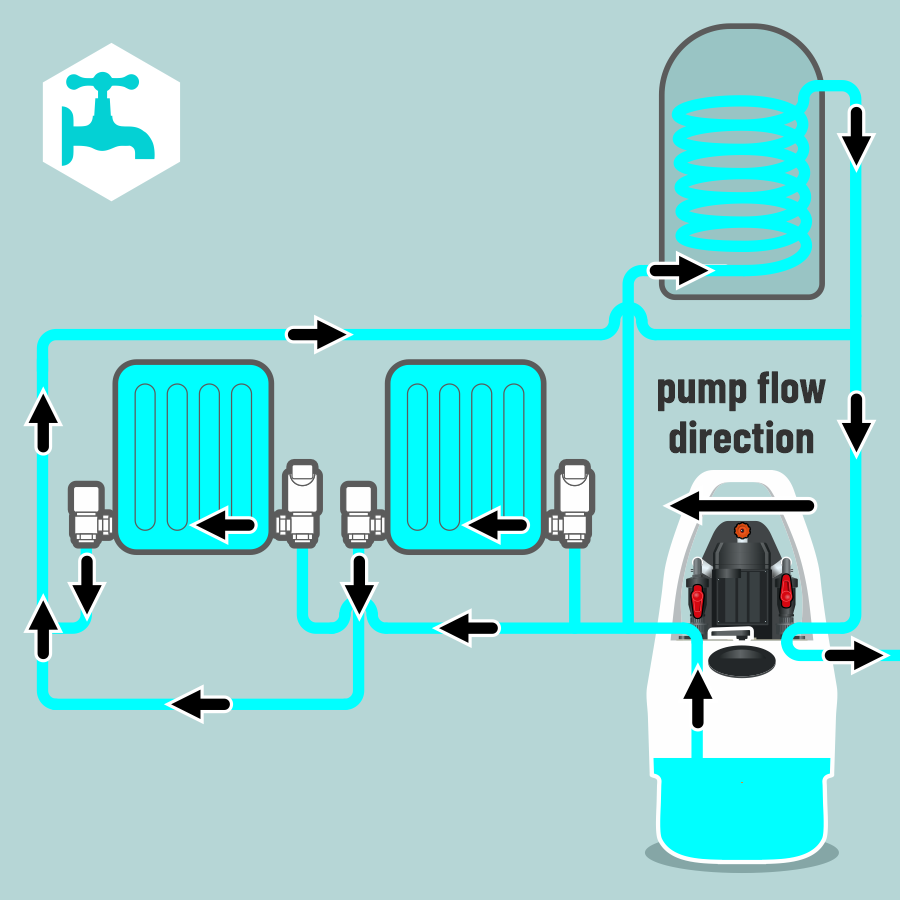

19 SET VALVES TO DUMP

- Isolation valve to the opposite side of flow direction is set upwards to "dump"

- Water inlet valve is balanced to maintain water level in the holding tank

20 DUMP RADIATORS & CYLINDER*

- System is wide open

- Dump to foul water waste drain *If cylinder is present

21 DUMP UNTIL WATER CLEARS

- System is wide open

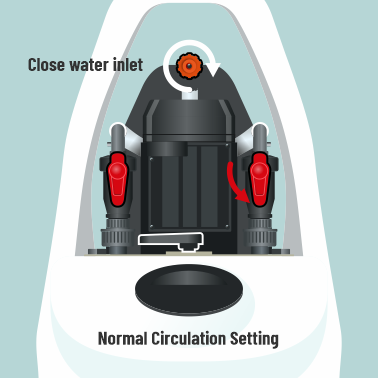

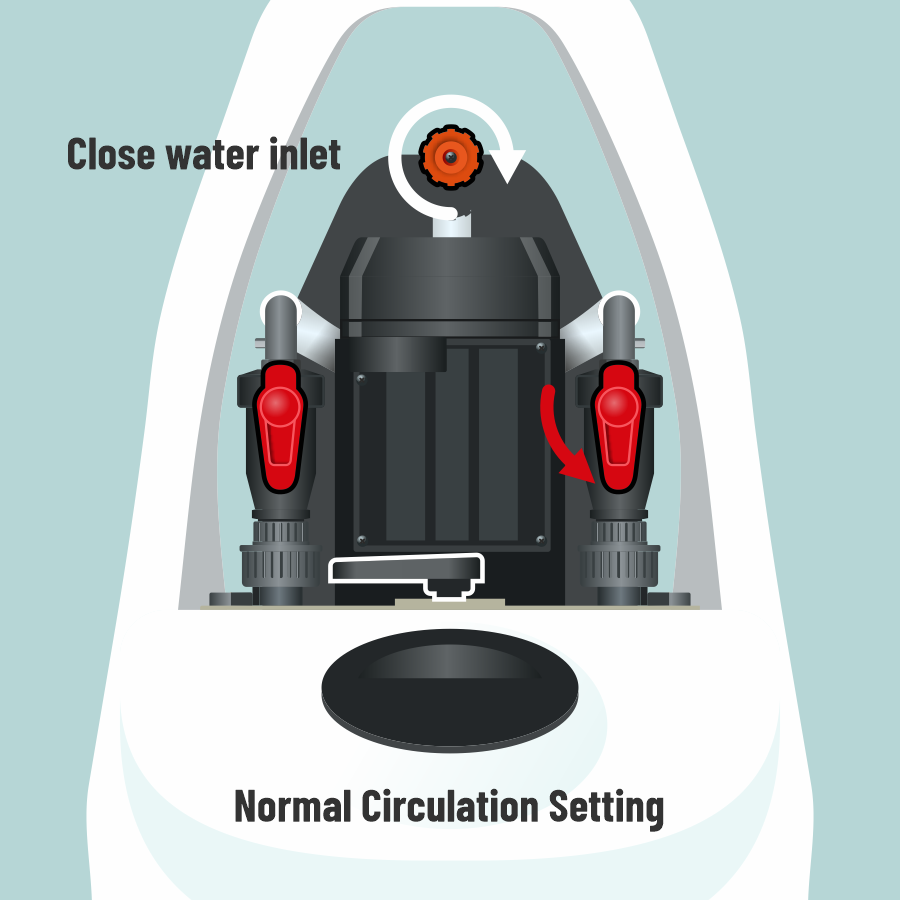

22 SET VALVES TO CIRCULATE

- Ensure water inlet valve is closed

- Reset isolation valve to downward position

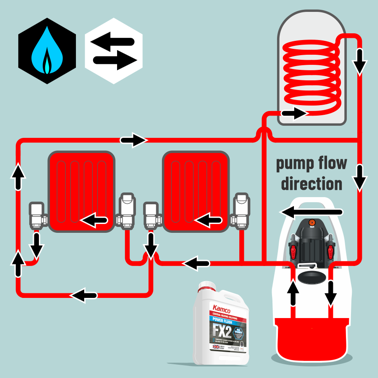

23 ADD POWER FLUSH FX2

- KAMCO recommends Power Flush FX2

- Max power, no need to pre-treat

- Add FX2 to holding tank via access cap

24 CIRCULATE FX2

- Circulate FX2 throughout system

- Turn on boiler, heat system to 50°C

- Turn off boiler

- Reverse flow regularly

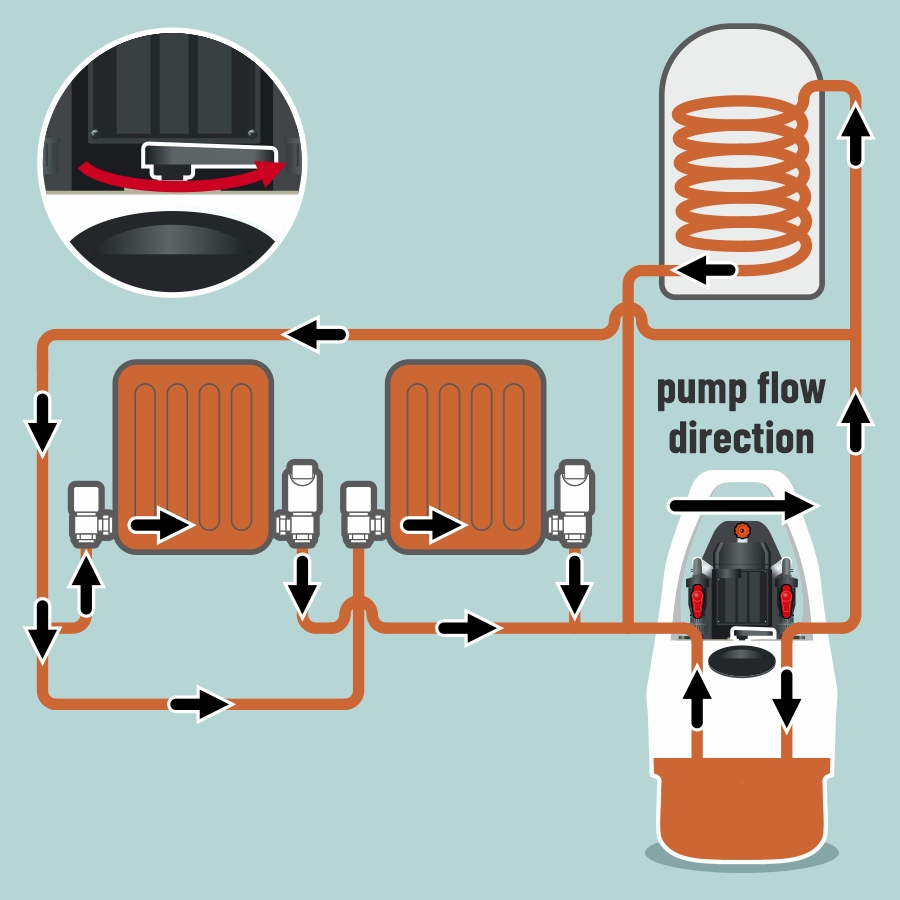

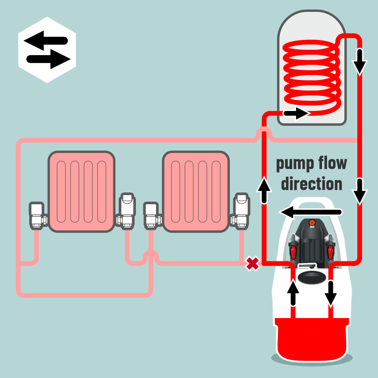

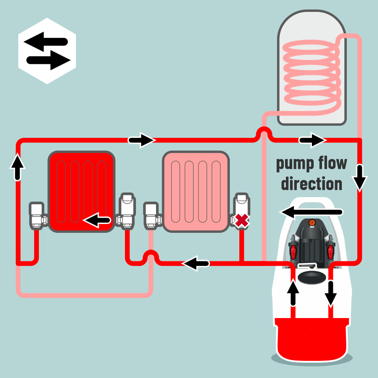

25 ISOLATE RADIATORS

- Circulate FX2 through cylinder coil only*

- Reverse flow regularly *if cylinder is present

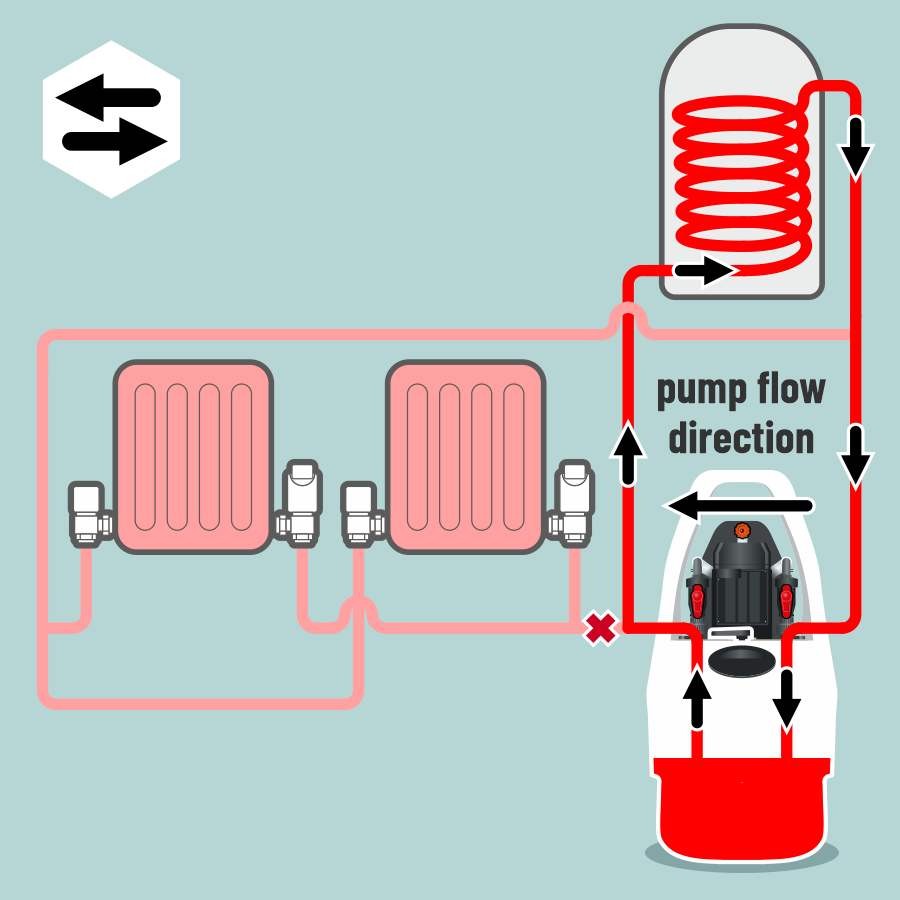

26 OPEN RADIATOR 1

- Isolate cylinder

- Open radiator 1

- Circulate FX2 through radiator 1 only

- Reverse flow regularly

27 OPEN RADIATOR 2

- Close radiator 1

- Open radiator 2

- Circulate FX2 through radiator 2 only

- Reverse flow regularly

- Repeat this process with all the remaining radiators on the system

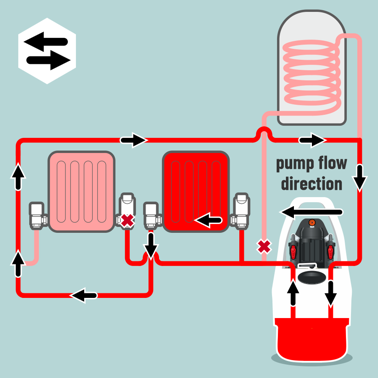

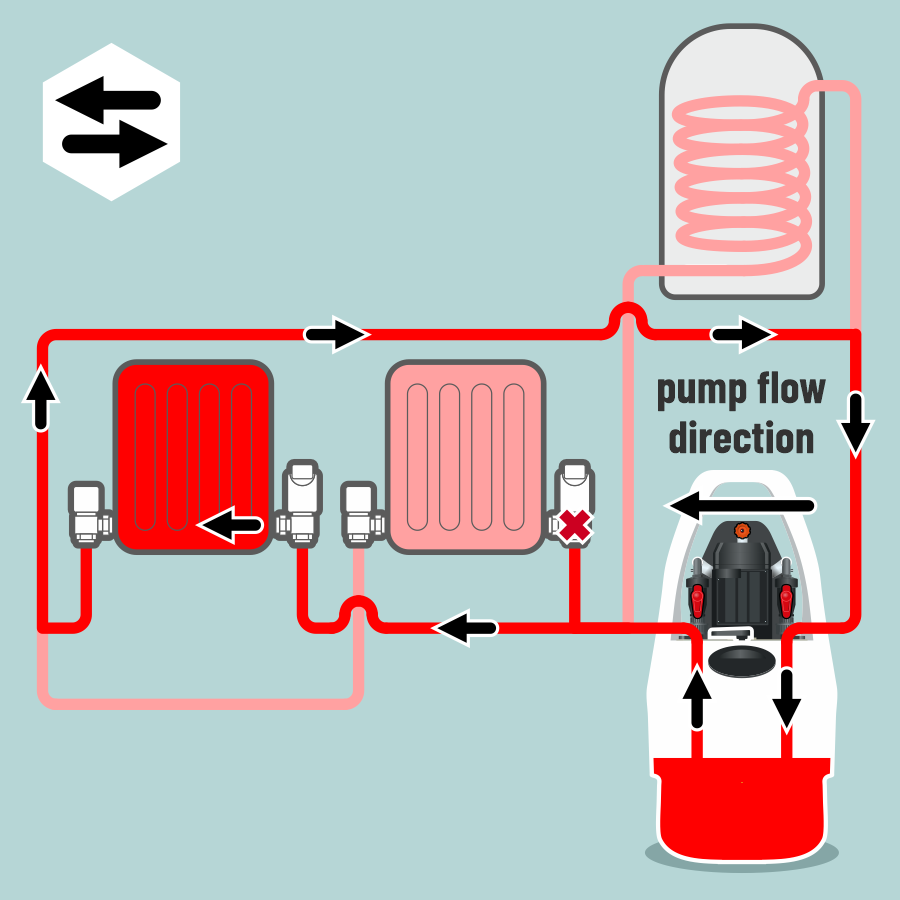

28 SET VALVES TO DUMP

- Isolation valve to the opposite side of flow direction is set upwards to "dump"

- Water inlet valve is balanced to maintain water level in the holding tank

29 DUMP RADIATORS

- Dump radiators individually and in reverse order

- Dump until water runs clear

- Repeat step on all radiators on the system

30 DUMP CYLINDER

- If no cylinder is present, go to next step

31 SET VALVES TO CIRCULATE

- Ensure water inlet valve is closed

- Reset isolation valve to downward position

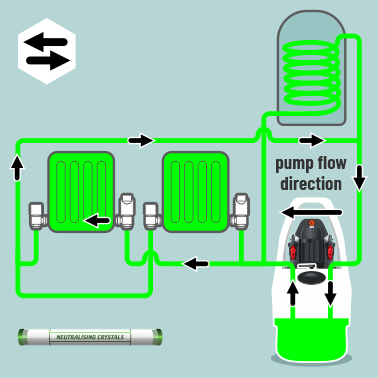

32 ADD NEUTRALISING CRYSTALS

- Open system

- Circulate neutralising crystals

- Reverse flow regularly

33 SET VALVES TO DUMP

- Isolation valve to the opposite side of flow direction is set upwards to "dump"

- Water inlet valve is balanced to maintain water level in the holding tank

34 DUMP NEUTRALISED WATER

- System is wide open

35 DUMP SYSTEM

- Dump until water runs clear

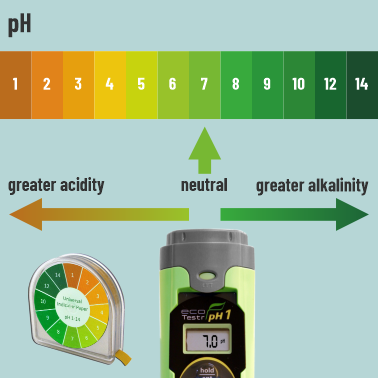

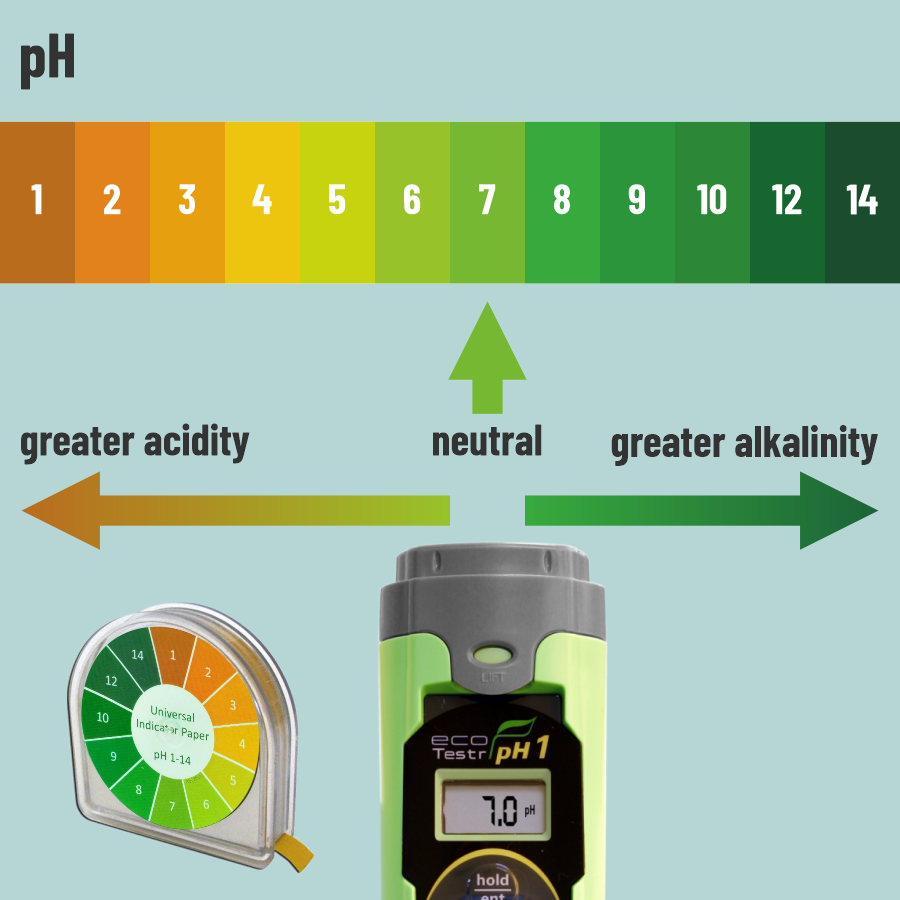

36 TEST DUMP WATER

- When dumped water runs clear test it to be sure

- Test with Turbidity Tube and TDS Meter

- If Power Flush FX2 chemical has been used,then test with pH Paper or pH Meter as well.

37 TEST FOR CONTAMINANTS

- Use a turbidity tube to ensure that no particulate or solid contaminants still present

- Use a TDS meter to ensure that no soluble contaminants are still present.

38 GET TO pH7 NEUTRAL

- Dumped water with a pH test of 7 is neutral

- Lower pH levels will lead to corrosion in the system

- Higher pH can damage aluminium if present

39 SET VALVES TO CIRCULATE

- Ensure water inlet valve is closed

- Reset isolation valve to downward position

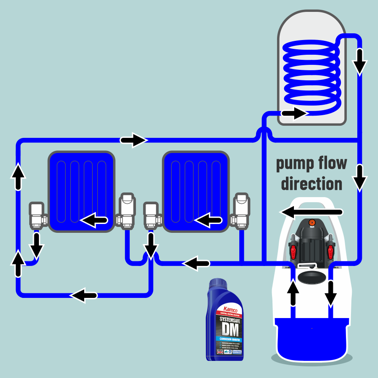

40 SYSTEMSAFE DM

- For best results Kamco recommends using SYSTEMSAFE DM corrosion inhibitor with every power flush

- Complies with: BS7593 and

Building Regulations Part L

41 CIRCULATE SYSTEMSAFE DM

- Add SYSTEMSAFE DM to holding tank

via access cap - Circulate SYSTEMSAFE DM

- System is wide open

42 DISCONNECT AND DUMP

- Turn Clearflow power off

- Disconnect flow and return from system

- Run flow hose to foul water drain waste

- Turn on Clearflow power, dump holding tank via flow hose to foul water waste

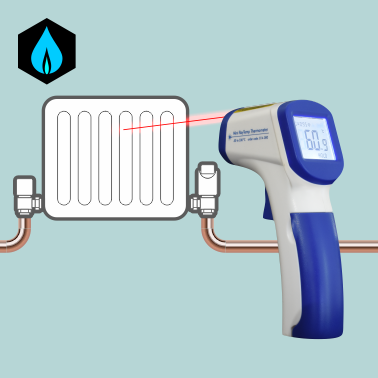

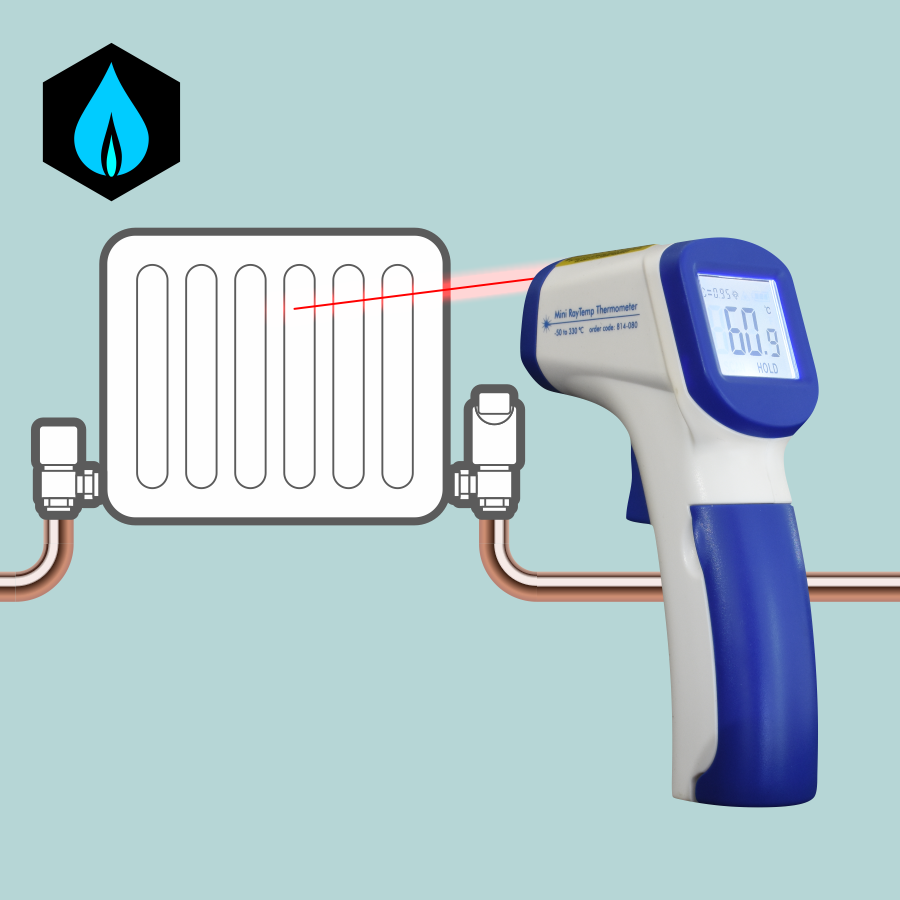

43 RADIATOR HEAT DISTRIBUTION

- Turn on boiler

- Use an Infrared Thermometer to demonstrate

more even heating of radiators with cold areas removed

44 LEAVE A RECORD

- Complete a Power Flushing Certificate to leave with the householder, retain the carbon copy for your records